Introduction

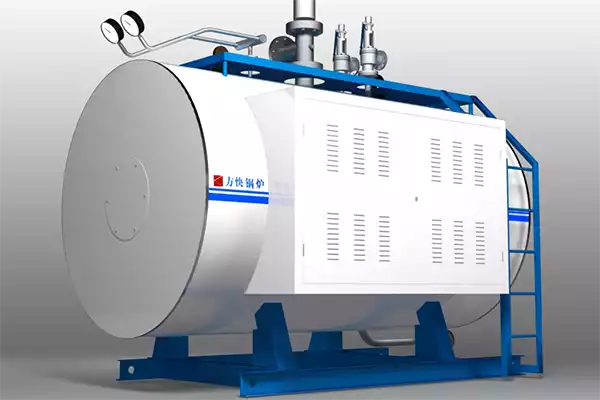

A steam boiler is a piece of equipment used to create steam. They are typically made from steel, copper, or brass. Steam boilers have many different parts with different functions all working together to make sure everything runs smoothly. In this guide, you will be able to learn in detail the components of a steam boiler. So that you can better understand it.

Burner

The burner is the part of the steam boiler that burns fuel to produce heat. The burner is connected to the furnace by a flame sensor, which detects when fuel has been ignited and allows gas or oil to flow into it. It’s typically located at the bottom of the steam boiler but can also be on top.

Combustion Chamber

The combustion chamber is the part of your steam boiler where fuel and air are mixed, ignited, and burned. It’s generally made from refractory materials that can withstand high temperatures without melting or breaking down. The combustion chamber accounts for about 10% of total heat transfer in a modern-day steam generator system. So it plays a vital role in keeping your home warm during cold winter months!

Heat Exchanger

The function of a heat exchanger is to transfer energy from one fluid to another by means of convection or radiation. Heat exchangers can be made of alloys such as nickel-based alloys, copper alloys, aluminum alloys, and stainless steel. These materials are often used in industrial processes. Because they are strong enough to withstand high temperatures without being damaged over time.

A common example of a boiler with a heat exchanger is an electric water heater, where hot water travels through pipes in your home or apartment building and exits into radiators. This way, you can enjoy warm floors when it’s cold outside!

Water level Indicator

A water level indicator is a mechanical device that uses a float to measure the level of water in the boiler. It is typically located on the water side of the boiler and indicates when you need to refill it with more water.

The purpose of this device is twofold. First, it allows you as an operator or engineer to know how much fuel you have left before refilling your fuel source. Second, it keeps track of how much steam is being produced by measuring its volume relative to how much water has been used up.

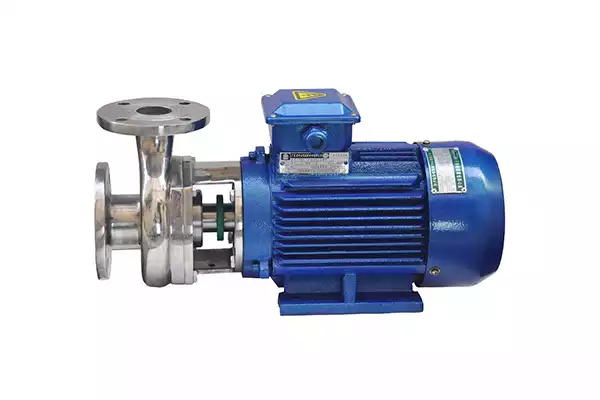

Circulator Pump

The circulator pump circulates water between the steam boiler and the feed pump. It consists of a rotating impeller or rotor inside an enclosed casing, with inlet and outlet ports.

The rotor is connected to a shaft that turns at high speed when power is supplied to it. As this happens, centrifugal force throws liquid outward from the center of rotation into each end of its chamber. It exists as pressurized steam through one port while returning as a coolant via another port back into your system’s plumbing lines.

Water Feed Pump

The water feed pump is a mechanical device that pumps water from the storage tank to a steam boiler. A water feed pump can be electric or gas-powered, and it can be either centrifugal or positive displacement in design. The vertical style is most common for home heating systems. However, horizontal pumps are more common in larger commercial applications because they’re easier to install and maintain.

The pump motor works by spinning gears that move liquid through pipes at high speeds (upwards of 10,000 revolutions per minute). Depending on how many stages of pumps you have installed in your system, there may also be valves between each one so that only one stage needs to work at any given time. This helps keep things running smoothly without tripping breakers or causing other problems with electrical circuits throughout your home.

Controls System

The controls system is used to monitor and control the steam boiler. It is usually installed in a separate room from the boiler itself, but can sometimes be located within it. The control system includes various sensors that detect conditions such as temperature, pressure, and water level inside of your boiler.

The purpose of these sensors is to ensure that your steam plant is running smoothly at all times so that you do not experience any unexpected outages or downtime due to malfunctioning equipment or defective parts.

Deaerator

Deaerators are used in steam boilers and central heating systems to remove dissolved gases from the water before it enters the heating system. Deaeration is an important step in the process of producing pure water for industrial use, as it ensures that no contamination occurs during the storage or transportation of your product.

Condenser

The condenser is a device used to convert thermal energy into mechanical energy. It is located at the end of a steam line, where it receives hot steam from its previous stage and converts it into water vapor. The condenser consists of pipes, tubes, and fins that have been designed specifically for this purpose.

The condenser’s function is to cool down this incoming flow of hot liquid so that it can be reused elsewhere in your system.

Economizer

An economizer can transfers heat from the flue gas to the feed water. It is used to recover heat from exhaust gases, or flue gases, that would otherwise be wasted. The typical application is in industrial steam boilers or power plants where large volumes of steam are generated.

An economizer works on the principle of “Latent Heat” – which means that when water changes state (i.e., becomes either liquid or vapor). It absorbs or gives off energy without changing the temperature at all!

Exhaust Stack

The exhaust stack is a vertical pipe that carries the hot flue gas away from the boiler. The position of this pipe must allow for a vertical rise, as well as being as high as possible. This allows for maximum heat transfer and prevents condensation in your home’s basement or crawlspace.

Expansion Tank

The expansion tank is a pressure safety device that helps prevent the steam from blowing off the safety valve. It’s basically just an oversized reservoir that stores excess water when it builds up in your boiler. When this happens, the water will flow into pipes and out through a drain valve at the bottom of your boiler.

When you have too much pressure inside your system, which can happen when there’s not enough water left in it to absorb all that heat energy. Therefore, you need something else besides just opening up more valves to release some pressure. Otherwise, those valves won’t hold forever!

Water Storage Tank

The water storage tank is used to store water, which will be heated in the steam boiler. It’s connected to the steam boiler and sits below. So that you can use gravity to help move water through your system without having to pump it around manually.

The size of your storage tank will depend on how much hot water you need at any given time. For example, if your family uses a lot of baths or showers every day then you might want an extra large capacity tank (or multiple smaller ones).

Superheater

The superheater can increase the temperature of the steam produced by the steam boiler, and the steam at this time is called “superheated steam”. In its simplest form, it consists of tubes through which water flows and is heated by exhaust gases from another part of the boiler system. Then, the steam passes into another set of tubes where it picks up additional heat. Finally, being injected into a turbine or condenser for use in generating electricity or driving machinery such as an electric locomotive.

Blowdown Tank

A blowdown tank is used to remove water from the steam boiler. It’s located at the bottom of the boiler so that it can collect any condensate that forms during operation. As steam passes through this area of your system, it will cool and condense into liquid form. This liquid must then be drained out as quickly as possible so that it doesn’t damage your system or cause other issues like corrosion or clogged pipes throughout your home or office building.

Safety Valve

A safety valve is a steam valve that opens automatically to release excess pressure. Safety valves are usually set at a pressure of 15 pounds per square inch (psi), but they can be set at different pressures depending on the type of boiler and its use.

Stop Valve

The stop valve is a device that stops the flow of steam when it is not needed. It can be opened or closed manually, but most modern boilers are equipped with automatic stop valves. The main purpose of this device is to prevent damage to your equipment and house if there is a rupture in your system.

Backflow Valve

A backflow valve is a check valve that prevents the backflow of water.The purpose of this device is to prevent contamination or damage to your steam boiler system by ensuring that no water enters it from sources other than its intended source.

Backflow valves are typically installed after pressure relief valves and before condensate drains, but they may also be placed at other locations within a steam heating system. It’s important to have a backflow valve on your steam heating equipment because it protects against flooding and keeps contaminants out of your pipes. Which could lead to corrosion and reduced performance over time if left unchecked!

Control Panel

The control panel is used to monitor and maintain the steam boiler. It can also be used to control it, but this depends on the type of control panel you have installed. A computerized system will allow for more precise monitoring of your boiler’s performance, whereas a simple switch may only allow you to turn it on or off.

Conclusion

A steam boiler is a complex machine that can be difficult to understand. But this guide has given you all the information you need to know about its main parts and how they work together. Hope you now already know what makes up a steam boiler, as well as its functions within one!

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies