The cost of an industrial electric boiler is around $4,500 – $48,000. They are a great way to heat your space. They are efficient, quiet, and easy to install. You can also add natural gas burners if you want to use the boiler as an alternate source of heat. In this article, we will answer all of your questions about industrial electric boilers: how they work, how long they last, what the efficiency is like, and more!

Is an industrial electric boiler worth it?

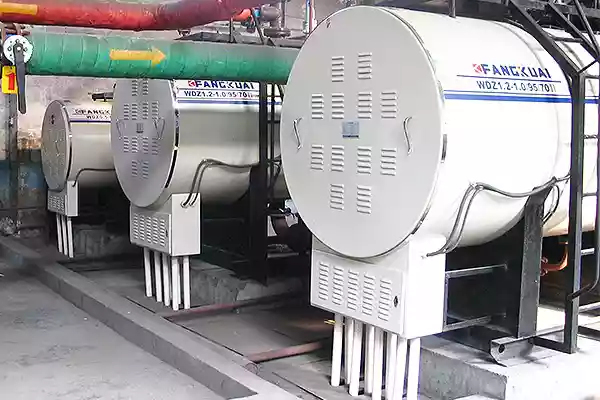

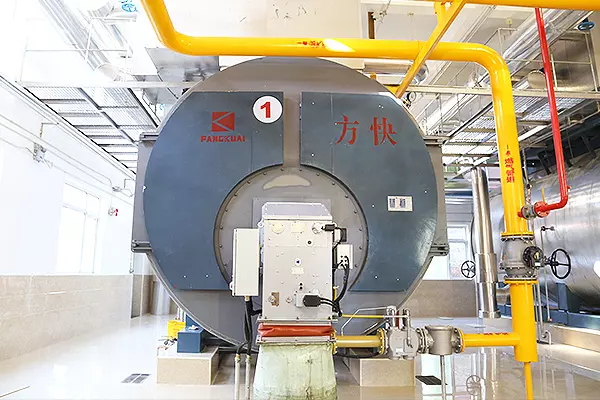

Industrial electric boiler manufacturers

Yes. In some industries, an industrial electric boiler is a good choice. This type of boiler is more efficient than gas or oil, cheaper to run, and quieter than their counterparts. For example, they can be used in the production of plastics and other materials where there is a need for high heat over long periods of time without interruptions. These boilers are also often more environmentally friendly because they do not produce any dangerous emissions (or at least less dangerous ones).

However, before considering investing in an industrial electric boiler it is important to find out if your industry could benefit from such a system. The best way to do this is by contacting professionals who specialize in this area and asking them what kind of equipment would suit your needs best!

Working principle.

Industrial electric boilers use a transformer, which is an electrical component that converts electricity into heat. The heat is then used to warm water up to 200 degrees Fahrenheit (F). This hot water is piped throughout your building and used to provide heat. It can also be used directly on some industrial processes like cooking food or sterilizing equipment.

In short, industrial electric boilers use electricity to heat water. The process starts when the transformer converts the electrical current into high-pressure steam. The steam then heats the water through a heating coil or boiler tube and transfers that heat to the building’s air distribution system.

Lifespan.

The life expectancy of industrial electric boilers can be as long as 20 years or more. These industrial boilers have a high level of durability, which means that they can withstand extreme weather conditions and heavy use without breaking down. Additionally, they are easy to repair when they do need servicing. They can last for 20 years or more, providing the boiler is well maintained.

Efficiency.

The efficiency of an industrial electric boiler is typically higher than that of natural gas, biomass, and steam boilers. The efficiency of an industrial boiler ranges from 85% to 98%, depending on the model. This is higher than the efficiency of a natural gas boiler, which typically runs at 80%. However, it’s lower than that of biomass boilers or steam boilers (99% and 99.5%, respectively).

The energy efficiency of an industrial electric boiler is stated as the ratio between the power output and input power. In general, lower heat losses lead to higher thermal efficiencies. Heat losses occur in boilers due to convection, radiation, and conduction. Conduction occurs when heat travels through the material used for the construction of the boiler itself; this means that less expensive materials such as steel will result in more conduction loss than expensive materials such as copper or aluminum.

Application field.

Industrial electric boilers are used for various heating and hot water applications in industrial settings. Their versatility and efficiency make them suitable for a wide range of industries and processes. Some common uses of it include:

Space heating: Electric boilers can provide heating for large industrial facilities, warehouses, production areas, and office spaces. They are particularly useful in applications where precise temperature control is required.

Process heating: Many industrial processes require a constant and controlled heat source. Electric boilers are well-suited for process heating in industries such as chemical manufacturing, food processing, pharmaceuticals, textiles, and plastics.

Hot water supply: Electric boilers can generate hot water for various industrial needs, such as in laundries, breweries, dairies, and hospitals. They are used for sanitizing equipment, cleaning, and general hot water supply.

Steam generation: Some industrial processes require steam for sterilization, heating, or power generation. Electric boilers can produce steam to meet the demands of such applications.

Multi-boiler installations: In some large industrial facilities, multiple electric boilers can be installed to work in parallel, providing redundancy and ensuring continuous heating and hot water supply.

Industrial electric boiler vs gas boiler.

Industrial electric boilers and gas boilers are both commonly used for heating and providing hot water in industrial settings. Each type of boiler has its advantages and disadvantages, and the choice between them depends on various factors, including cost, energy efficiency, environmental considerations, and specific operational requirements.

Energy source

Electric boilers: Electric boilers use electricity as their primary energy source. They do not produce any direct emissions on-site, making them environmentally friendly at the point of use.

Gas boiler: Gas boilers utilize natural gas or propane as their fuel source. The combustion of these fossil fuels releases carbon dioxide and other emissions, contributing to greenhouse gas emissions and air pollution.

Efficiency

Electric boilers: Electric boilers are known for their high energy efficiency because they convert nearly all the electrical energy into heat, losing very little energy during operation.

Gas boiler: Gas boilers can also be highly efficient, especially if they are of the condensing type, which recovers heat from exhaust gases. However, some energy is lost during the combustion process.

Cost

Electric boiler: The cost of electricity can vary significantly based on location and time of use. Electric boilers tend to have lower upfront costs compared to gas boilers. However, the operational costs may be higher due to the cost of electricity.

Gas boiler: Natural gas is often cheaper than electricity, which can make gas boilers more cost-effective in the long run. However, gas boilers may have a higher upfront cost, depending on the infrastructure required for gas supply.

Installation and infrastructure

Electric boiler: Electric boilers are generally easier to install since they do not require flue systems or fuel supply lines like gas boilers. They also do not need ventilation, making them more flexible in terms of installation location.

Gas boiler: Installing gas boilers may require additional infrastructure. Such as gas supply lines, flues, and ventilation systems. Which can add to the installation’s complexity and cost.

Maintenance

Electric boiler: Electric boilers generally have fewer moving parts, which can result in lower maintenance requirements and costs compared to gas boilers.

Gas boiler: Gas boilers may require more frequent maintenance due to the combustion process and the complexity of some gas boiler models.

Are industrial electric boilers more expensive?

The cost of an industrial electric boiler is higher than that of a gas boiler, as you would expect. The cost depends on the size and capacity of the boiler, and how much electricity it will use. However, this cost is lower than that of steam boilers because they need less maintenance and are more energy efficient.

The main advantage of using an electric boiler over other types is its ability to be used for heating in any weather conditions, including extremely cold temperatures when no other form of heating can operate effectively or safely (such as in winter).

How much does an industrial electric boiler cost?

Industrial electric boiler price

The cost of an industrial electric boiler depends on how much you’re willing to pay, but it’s safe to say that the price will be somewhere between $4,500 and $48,000. The cost of an industrial electric boiler depends on several factors:

- Size: The size of your boiler will determine how large your facility is. A larger facility needs more power and therefore may need a larger industrial boiler.

- Brand: Company brand and reputation are important when purchasing an industrial water boiler because they can indicate the quality of their products. Some brands have better reputations than others, which means they make better products that last longer.

- Features: The number and type of features available will affect the cost of an industrial boiler. More expensive models have more features such as automatic error detection systems that can help prevent overheating and reduce maintenance downtime costs later on in life spans.

- Installation: If you’re installing this yourself instead of hiring someone else to do so then there are many installation costs associated with doing so including buying tools needed for installation like wrenches and screwdrivers before starting up work! These types could cost anywhere from $30 -$50 depending on where you live too.

| Boiler Size (kW) | Efficiency (%) | Cost ($) |

|---|---|---|

| 100 – 1,000 | 90 | 4,500 |

| 95 | 5,800 | |

| 98 | 7,200 | |

| 1,000 – 2,000 | 90 | 5,000 |

| 95 | 6,500 | |

| 98 | 8,000 | |

| 2,000 – 3,000 | 90 | 8,500 |

| 95 | 10,500 | |

| 98 | 12,500 | |

| 3,000+ | 90 | 37,500+ |

| 95 | 44,000+ | |

| 98 | 48,000+ |

Conclusion.

Industrial electric boilers are a great option for businesses that need to heat their facility and do not have access to natural gas. They are an environmentally friendly way to heat your home or business, as well as cost-effective because they use less energy than traditional systems such as furnaces or baseboard heating units do.

FAQs.

What is an industrial electric boiler?

An industrial electric boiler is a heating device specifically designed for large-scale industrial applications. It uses electricity as its power source to generate heat and provide hot water or steam for various industrial processes.

How do industrial electric boilers work?

Industrial electric boilers work by utilizing electric resistance heating elements to generate heat. When electricity flows through these elements, they heat up, transferring the heat energy to the surrounding water or fluid, which then circulates through the system to provide the required heat.

What is the difference between industrial and commercial boilers?

The main difference between industrial and commercial boilers lies in their intended applications. Industrial boilers are designed to handle large-scale operations processes in industries like manufacturing, while commercial boilers are typically used for heating and hot water purposes in offices, hotels, or hospitals.

How much electricity do industrial electric boilers use?

Industrial electric boilers consume between 90 - 980 kW/h, depending on factors such as boiler size, efficiency, and usage. In general, larger industrial electric boilers consume large amounts of electricity, ranging from a few hundred kilowatts (kW) to several megawatts (MW).

How much does an industrial electric boiler cost?

The cost of an industrial electric boiler is between $4,500 and $48,000. But can vary based on several factors, including its capacity, design, features, and additional components required for specific applications. They can offer long-term cost savings in terms of energy efficiency and maintenance.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies