The prices of oil steam boilers range from $2,500 to $18,000. The specific price depends on the size, model, brand, and other factors of the equipment. Reading this guide will help you learn more about oil-fired boilers and costs to save you money.

What is an oil steam boiler?

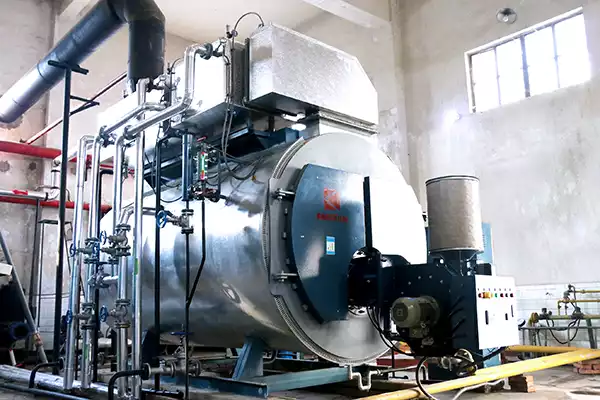

An oil-fired steam boiler is a type of boiler that burns oil to produce steam. These boilers are used for heating and industrial processes, as well as commercial and residential buildings. They’re also used in industrial processes, such as chemical manufacturing and food production.

How does an oil steam boiler work?

An oil steam boiler works by burning oil in the furnace to heat water. The hot water is then pumped through a heat exchanger, where it transfers its heat to incoming cold water. This process causes the water’s temperature to rise and become superheated steam that can be used for industrial processes or as part of your home heating system.

What is the difference between steam boilers and oil boilers?

The main difference between steam boilers and oil boilers is the fuel they use. Steam boilers use water as their energy source, while oil boilers use oil as their energy source. Second, steam boilers tend to be more efficient than their counterparts but are also more compact in size and therefore cost less money to purchase and operate over the long run.

What are the pros and cons of oil-fired steam boilers?

Pros:

- Oil-fired steam boilers have high energy efficiency and can achieve fuel efficiency ratings of up to 87% or more.

- Oil is a readily available fuel source and is generally less expensive than other fuel options such as propane or natural gas.

- Oil-fired boilers have a long lifespan and can last up to 30 years or more with proper maintenance.

- Oil steam boilers can produce high levels of heat quickly and consistently, making them a reliable choice for heating large spaces or industrial processes.

Cons:

- Oil-fired steam boilers require a storage tank for the oil, which can take up a significant amount of space and require additional maintenance.

- Oil steam boilers can emit air pollutants and contribute to air pollution, which can be a concern in areas with poor air quality.

- Oil fired steam boiler require regular maintenance to ensure optimal performance and prevent breakdowns or malfunctions.

- Oil prices can be volatile and subject to sudden price spikes, which can impact the cost of heating with an oil-fired steam boiler.

How do you choose an oil-fired steam boiler?

When choosing an oil-fired steam boiler, it’s important to consider several factors such as:

- Size: The size of the boiler should be appropriate for the heating needs of your home or building. A boiler that is too small will struggle to provide adequate heat, while one that is too large will waste energy and money.

- Efficiency: Look for a boiler with a high efficiency rating to ensure that you are getting the most out of your fuel source. Boilers with an AFUE (annual fuel utilization efficiency) rating of 85% or higher are considered to be highly efficient.

- Fuel source: Oil is the most common fuel source for steam boilers, but it’s important to consider the availability and cost of oil in your area before making a decision.

- Brand and model: Choose a reputable brand and model that has a good track record of reliability and performance. Read reviews and ask for recommendations from trusted sources.

- Maintenance and service: Consider the availability and cost of maintenance and service for the boiler, as regular maintenance is necessary to ensure optimal performance and prevent breakdowns.

- Cost: The cost of the boiler and installation should be considered in relation to the expected lifespan and energy savings of the unit. It’s important to find a balance between upfront costs and long-term savings.

How much does it cost to replace an oil steam boiler?

The cost of replacing an oil steam boiler depends on a number of factors, including the size of the unit and whether it’s new or used. The table below shows the cost when replacing oil-fired boilers of different sizes and efficiencies.

| Boiler Size | Efficiency | Cost Range |

|---|---|---|

| 50-70k BTU | 80-85% | $2,500-$4,500 |

| 50-70k BTU | 86-90% | $3,500-$6,500 |

| 70-90k BTU | 80-85% | $3,500-$6,000 |

| 70-90k BTU | 86-90% | $4,500-$8,000 |

| 90-120k BTU | 80-85% | $4,500-$7,500 |

| 90-120k BTU | 86-90% | $6,000-$10,000 |

How much does an oil boiler cost?

The cost of an oil boiler will vary depending on the size, type, and brand of boiler you choose. The table below is some cost details for different sizes of oil fired boilers.

| Boiler Size | Main Body Cost | Installation Cost | Repair Cost | Maintenance Cost | Service Cost |

|---|---|---|---|---|---|

| 50-70k BTU | $2,000-$3,500 | $1,500-$3,000 | $150-$500 | $150-$300 | $100-$200 |

| 70-90k BTU | $3,000-$5,000 | $2,000-$4,000 | $200-$600 | $200-$400 | $150-$250 |

| 90-120k BTU | $5,000-$10,000 | $3,000-$5,000 | $300-$800 | $300-$500 | $200-$300 |

Conclusion.

In conclusion, oil steam boilers are a great choice for anyone looking for a high-quality heating system. They are efficient and reliable, but they also have some drawbacks that you should be aware of before making your decision. We hope this article has helped answer some questions about oil boilers and given you some ideas on how much they cost!

FAQs.

Do steam boilers use oil?

Yes, some steam boilers use oil as their fuel source, known as oil-fired steam boilers. These boilers burn heating oil to produce the steam needed for various heating and industrial applications.

How does an oil steam boiler work?

An oil steam boiler works by burning oil to heat water, which then generates steam to provide heat for a building. The steam is distributed through pipes and released into radiators, which then release heat into the room.

How efficient is an oil steam boiler?

The efficiency of an oil steam boiler can vary but typically ranges from 80-90%, depending on factors like maintenance and system design. Regular maintenance and proper usage can help improve efficiency and save on energy costs.

How much oil does a boiler use per day?

The amount of oil a boiler uses per day depends on usage and can range from 24-72 gallons per day. Factors such as the size of the boiler, the age and condition of the equipment, and the building's heating needs can also affect daily oil usage.

What is the difference between gas and oil steam boilers?

The primary difference between gas and oil steam boilers lies in their fuel source. Gas boilers use natural gas, while oil boilers use heating oil. Both serve the same purpose of producing steam for heating.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies