If you’re looking for an efficient and reliable way to heat your home or business, diesel hot water boilers should be on your radar. Diesel-fired boilers provide comfort and convenience using diesel as a fuel source. In this comprehensive guide, we’ll cover everything you need to know about diesel water boilers, from how they work to tips for choosing the suitable model.

You’ll learn about the benefits of diesel boilers, the different types available, key factors like efficiency and emissions, cost considerations, maintenance needs, ideal applications, and more. Whether you want to heat your house or need a solution for your commercial building, this guide will ensure you make an informed decision about diesel steam boilers.

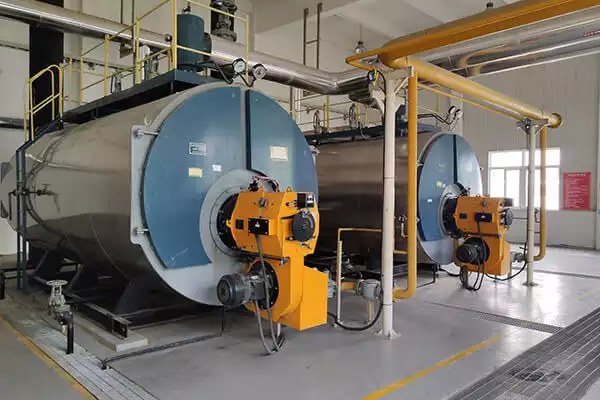

What is a diesel hot water boiler?

A diesel hot water boiler is a heating system that uses diesel fuel to heat water for residential or commercial use. They are commonly used in areas where natural gas is not available, and they can be used for a variety of heating applications such as baseboard heaters, radiators, and radiant floor heating.

How do diesel boilers work?

The operating principle of a diesel boiler is relatively straightforward. It consists of two main components – a burner unit and a heat exchanger. The burner uses a diesel fuel source to provide heat through combustion.

This heat is then transferred to water circulating through the heat exchanger pipes. The hot water flows from the boiler and into your home’s radiators, underfloor heating systems, or hot water taps. Here are some key points about the diesel-fired boiler working process:

- The diesel burner uses an atomizing nozzle to spray the fuel in a fine mist into the combustion chamber. The fuel mist mixes with air and ignites, generating flames.

- This combustion reaction heats gases inside the chamber to extremely high temperatures of over 2000°F.

- The hot gases pass over the heat exchanger, which contains pipes full of water from the heating system.

- Heat gets from the gases into the metal heat exchanger and the water. This thermal energy transfer heats the water to the required system temperature.

- The water then circulates the home, releasing heat through radiators, underfloor pipes, or taps. This provides the desired heating and hot water.

The critical difference from gas boilers is that diesel fuel is stored in an external tank rather than drawn from the main utility gas pipes. Diesel also packs more energy density than gas, producing greater heat output from smaller quantities. An electric boiler operates without combustion, heating elements to warm the water.

Types of diesel boilers

There are a few main configurations of diesel boilers available:

- Standard Efficiency –These affordable boilers are 80-85% efficient. A good option for minor, occasional heating needs.

- High Efficiency – Features an enhanced heat exchanger that captures more waste heat. Efficiency reaches 90-95%.

- Condensing – Fitted with an extra heat collector to reuse latent heat. Most efficient at 95-98%.

- Compact/Combi – Smaller integrated units designed for convenience. It may have limited heating capacity.

- External – Larger boilers installed outdoors instead of inside the property. Include weatherproof casing.

Benefits of using a diesel

Diesel has several advantages that make it suitable for boiler fuel:

- High energy density: 1 liter of diesel provides around 10kWh of energy through burning.

- Clean burning: Modern diesel boilers combust very efficiently, producing low emissions.

- Transport and availability: Diesel fuel supply is widely available for delivery or pickup.

- Storage: Diesel can be safely stored long-term in external tanks with minimal deterioration.

- Cost: Diesel tends to be more affordable than other liquid fuels like heating oil.

- Reliability: Provides heat even in off-grid or rural areas without mains gas or electricity.

The primary considerations are installing a suitable diesel tank for storage and arranging diesel delivery or pickup. Overall, diesel offers an efficient, pragmatic heating solution. Unlike natural gas, propane, or biomass, diesel provides a versatile and accessible fuel option.

Applications of diesel boilers

Some ideal situations where a diesel boiler can provide an efficient and cost-effective heating solution include:

Residential home heating

- Off the gas grid, rural/country houses

- Remote locations without mains electricity

- Large properties requiring greater heat output

Commercial/Industrial

- Agricultural facilities like greenhouses and farms

- Construction sites and temporary camps

- Food production factories

- Warehouses and workshops

Case studies

One homeowner in an off-grid rural property installed a Firebird high-efficiency diesel hot water boiler, which provided economical and reliable heating even through cold winters with low outdoor temperatures.

An industrial factory switched its gas boiler system over to diesel. This gave them the required heat output in their large spaces without costly expansion of their gas supply infrastructure.

How much diesel does a diesel heater use per hour?

The diesel consumption rate of a diesel heater can vary depending on several factors, including the heater’s rated output, efficiency, operating conditions, and the desired temperature. It is important to refer to the manufacturer’s specifications and guidelines for accurate information on fuel consumption. However, I can provide you with a general estimation.

In general, diesel heaters have a fuel consumption rate that is typically expressed in liters per hour (L/hr) or gallons per hour (GPH). The fuel consumption can range from around 0.2 to 2 liters per hour, depending on the size and type of the heater.

For example, a small diesel heater with a rated output of 10,000 BTU/h (British Thermal Units per hour) may have a fuel consumption rate of around 0.2-0.3 liters per hour. A larger diesel heater with a rated output of 50,000 BTU/h may have a fuel consumption rate of around 0.5-0.8 liters per hour. These figures are just rough estimates and can vary depending on the specific model and other factors.

The cost of diesel boiler

Here are the main costs associated with installing and running a diesel hot water boiler:

- Boiler price ranges from $2000 for a standard model to $4000 for a top condensing boiler.

- Installation – Plumbing, electrical work, flue, and labor will likely cost $1000 to $2000.

- Fuel tank – Required diesel tank starts around $1000 for a basic 460L model. Expect closer to $2000 for larger tanks.

- Fuel usage – Approximately 1-2 liters of diesel fuel per day, depending on heating duration and outside temperature.

- Maintenance – Annual service costs around $150. Replacing parts like electrodes may be needed every 5-10 years.

Overall, a new diesel hot water boiler represents an investment of $5,000 to $8,000. This is on par with standard efficiency gas boilers but can be higher than basic electric or heat pump systems. However, diesel boilers offer reliable thermal output with relatively low running costs.

Maintenance and servicing

Diesel boilers are pretty robust and require minimal maintenance:

- Annual service by a qualified technician to clean and inspect components.

- Periodic replacement of electrodes and nozzles due to wear – usually after many years of usage.

- Inspect hoses, pumps, and fittings during service for leaks or issues.

- Check the flue vent annually and clear any debris blockages.

- Top up any corrosion inhibitor added to the heating system.

- Bleed radiators as needed to release trapped air.

- Clean the heating filter mesh as part of the service to remove buildup.

More intensive maintenance is typically needed every 5-10 years, including replacing the pump, heat exchanger, or other components. Most boiler manufacturers provide detailed servicing procedures. A reputable brand like Firebird offers a 5-year warranty on the heat exchanger for peace of mind.

Top 5 diesel boiler manufacturers

When choosing a diesel boiler, choose a reputable brand offering quality construction and efficient operation. The top models 2023 feature advanced designs for efficiency, reliability, and convenient installation.

Firebird Enviromax Heat-Pac C35 External

The Firebird Enviromax Heat-Pac C35 External is an excellent external wall-hung boiler option. With 35 kW output, it can heat homes to 300 sqm. Key features include a durable stainless steel heat exchanger, low NOx blue flame burner technology, and wet baseload capability.

Grant VortexBlue Combi 21kW

The Grant VortexBlue Combi 21kW is an excellent choice for a powerful but compact combi boiler. The condensing boiler has a 21 kW output for rapid heating and hot water production. Weighing just 55kg, the unit is lightweight and easy to install. It achieves an impressive SAP 2009 gross seasonal efficiency of 93%.

Warmflow Agentis Plus 27-33kW

Warmflow offers the Agentis Plus series of diesel boilers ranging from 27 to 33 kW capacities. The units are designed for straightforward installation and maintenance. An integrated multi-purpose control panel lets you monitor boiler operation.

Worcester Bosch Greenstar Heatslave II 25/32

Worcester Bosch produces the reliable Greenstar Heatslave II series, available in 25 or 32 kW models. The boilers feature exceptional fuel efficiency of up to 97%, achieved through advanced controls and high-quality components. They can also be integrated with Greenskie solar thermal systems.

Firebird Enviroblue Combi-Pac C26

Finally, the Firebird Enviroblue Combi-Pac C26 is an excellent 26kW combi boiler suitable for homes up to 220m2. Its high-performance duplex stainless steel heat exchanger provides lasting durability. Like other units mentioned, it can be combined with renewable solar heating.

Investing in a premium diesel boiler from one of these trusted brands will provide reliable performance and efficiency for years of comfortable heating.

Conclusion.

Diesel hot water boilers offer a versatile heating solution that is both efficient and cost-effective. From the intuitive working principle to considerations like fuel storage and maintenance requirements, this guide covers everything needed to decide if a diesel boiler is the right choice. Models from leading brands like Firebird provide the latest low-emission burner technology and robust design for lasting performance.

A diesel boiler should be strongly considered for homes and businesses located off the natural gas grid or requiring high heat output. They allow you to leverage the accessibility of diesel fuel for conveniently warm and comfortable indoor heating and hot water year-round.

FAQs.

What is the cost of diesel boiler installation?

Depending on the complexity, installation costs can range from $1000 to $2000. This covers plumbing, electrical work, flue installation, and labor.

How long do diesel boilers last?

Properly maintained, a high-quality diesel boiler can provide 15-20 years of reliable operation before needing replacement.

Do diesel boilers need electricity?

Diesel boilers run solely on diesel fuel and do not require electricity. However, the circulating pumps, control systems, and other accessories will need power.

What maintenance is required?

Essential annual servicing to check components and clear debris. More intensive maintenance is needed every 5-10 years to replace parts like pumps and heat exchangers.

Can diesel boilers provide domestic hot water?

Yes, diesel combis and system boilers can provide hot water to taps in addition to central heating by using an indirect cylinder or plate heat exchanger.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies