An industrial gas boiler is a type of heating system that uses natural gas to produce hot water and steam. A commercial or industrial boiler is designed to heat large buildings, such as factories, warehouses, and office spaces. There are different types of industrial boilers available so it is important that you choose the right one for your needs.

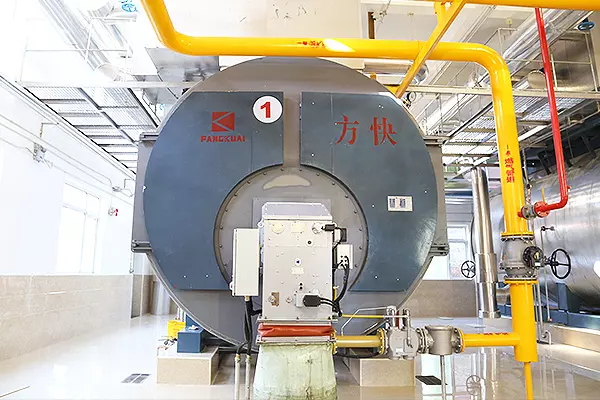

What does an industrial gas boiler look like?

An industrial gas boiler looks like a large metal box with a chimney on top. It can be anywhere from six feet to 10 feet high, depending on the size of your building and its heating needs.

The boiler itself weighs about 1,000 pounds (453 kilograms) and is installed in a basement or boiler room. It’s usually connected to the rest of your plumbing system by means of pipes that run through walls and floors or underground between buildings.

Because they’re so heavy and large, industrial gas boilers are usually installed by professional plumbers who know how to handle such big projects. You’ll also need an expert if you want one for your home; installing an industrial-sized unit in your house would require extensive modification of your existing structure—and even then, it might not fit!

Industrial gas boilers are usually used in commercial buildings like offices or schools because they provide enough heat for many different rooms at once; this is especially true when combined with radiant heating systems that keep radiators away from walls so all surfaces stay warm at once (rather than just those near radiators).

How does an industrial gas boiler work?

In a nutshell, an industrial gas boiler works by heating water to create steam. The heat is created through the combustion of natural gas or fuel oil in the furnace of the boiler. The process begins with air being drawn into the boiler through an air intake vent, and this air is then mixed with fuel in a combustion chamber where it’s converted into thermal energy (heat). This heat then travels up to a series of tubes inside the furnace, eventually reaching temperatures that exceed 1,000°F (538°C).

The hot gases produced during combustion travel up through these tubes where they’re directed over a series of high-temperature burners. These burners are surrounded by thousands of small nozzles; when lit by electricity they provide enough heat to raise water temperatures far beyond what could be achieved through direct contact with open flame alone—even if that flame was hot enough (which it isn’t). As this superheated water rises inside these tubes it expands rapidly due to its increase in volume and pressure; this causes more heated water from below the surface level to rise up towards them until all available space has been filled within their structure.

What is the purpose of an industrial gas boiler?

Industrial gas boilers are used to heat water, steam, or air. The boiler heats the water and converts it into steam. The steam then powers a turbine which generates electricity or drives a generator to produce electricity from the generator’s rotating shaft. Industrial boilers can also be used to power an engine that will then drive a generator with its rotating shaft.

Industrial boilers can also be used directly in the industrial process by converting their thermal energy into mechanical energy without using turbines or engines.

How long do industrial boilers last?

The short answer to this question is “it depends on many factors.” The length of time that your industrial gas boiler will last depends on the quality of materials used in its construction and installation. The more expensive models are made with higher-quality materials, which means they can withstand more wear and tear over a longer period of time than cheaper models.

Furthermore, if you choose an expert gas engineer to install your industrial boiler for you then this will also lengthen its lifespan. In general terms, however, most industrial boilers tend to last between ten and thirty years before needing replacement or repair work (or both).

How much does an industrial package boiler cost?

The cost of an industrial boiler will vary depending on the type and size you choose. Industrial gas boilers are typically less expensive than oil boilers, but both can cost anywhere from $10,000 to $50,000. However, if you’re looking for something more affordable or want to save some cash on installation costs by installing it yourself, there are options like hot water boilers that cost as little as $2,500.

Conclusion.

Industrial gas boilers are a great option for businesses that need to heat large spaces, such as warehouses or factories. They can be used to heat water and air, but they aren’t designed for residential use because they’re too powerful and expensive for most people’s needs.

FAQs.

Why use natural gas in industrial boilers?

Natural gas is preferred for industrial boilers due to its cost-effectiveness, clean-burning nature, and widespread availability. It reduces emissions and contributes to lower operational costs.

Are there different types of industrial gas boilers for various applications?

Yes, there are diverse types, including fire-tube, water-tube, and condensing boilers. Each is suited to specific industrial needs, from space heating to industrial processes.

What factors determine the size of an industrial gas boiler?

Boiler size depends on factors such as required hot water volume, temperature, load fluctuations, and specific application needs to ensure efficient and cost-effective operation.

How can industrial gas boilers meet emissions regulations?

Industrial gas boilers can comply with emissions regulations through technologies like low-NOx burners, selective catalytic reduction (SCR), and continuous emissions monitoring systems (CEMS).

How can industrial gas boilers be more energy-efficient and cost-effective?

Industrial gas boilers can improve efficiency through regular maintenance, advanced control systems, and the use of economizers to recover waste heat, reducing energy consumption and operating costs.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies