The cost of a new boiler circulating pump between $200 and $800, depending on the brand, model and size of your existing unit. A boiler circulating pump is a type of centrifugal pump that circulates water and steam in a heating system. Because it uses centrifugal force to push liquid through the system and transfer heat, it’s also called a centrifugal pump. The heating system uses boiler circulating pumps to move water through its pipes and radiators. Boiler circulators can also be used for water heating or space conditioning systems that use large volumes of hot water for everyday tasks like laundry or dishes.

What is a circulating pump?

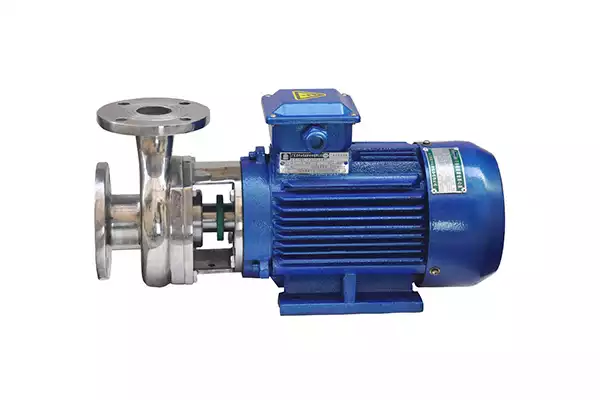

Circulator pump

A circulating pump is a mechanical device that moves fluid by means of a rotating impeller. It is used to circulate fluids such as water, oil, or liquid fertilizer through closed piping systems.

There are three parts of a circulating pump: the casing, the motor and shaft assembly, and the impeller.

The casing holds all the other parts together and protects them from damage. The motor and shaft assembly consists of two main components: an electric motor that powers the pump, and an attached shaft that transfers power from the electric motor to turn its impeller blades. The impeller does what you would expect; it circulates liquid through your pipes!

There are three types of circulating pumps: centrifugal pumps (or axial flow), turbine pumps (also called positive displacement), and mixed flow pumps. These can be further divided into subtypes based on their use or design specifics such as discharge direction (suction side vs discharge side).

Working principle.

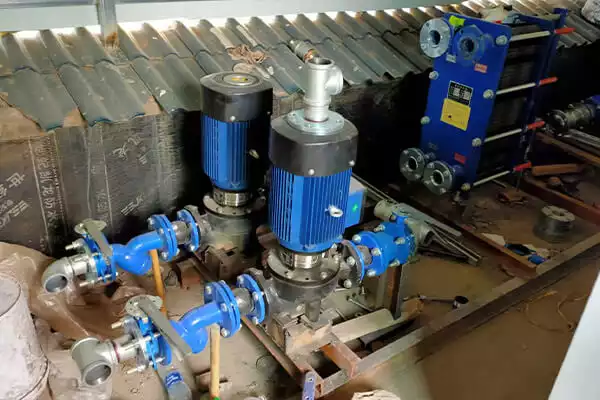

Circulator pump for boiler

A circulating pump is a type of electric motor that moves water through a system. A boiler-circulating pump, for example, uses an electric motor to circulate water through a boiler. This circulation allows the fuel used to heat the water in the boiler (oil or gas) to be used more effectively and efficiently by ensuring that all parts of the system receive adequate heat at all times.

When most people think about how a circulating pump works, they visualize an impeller (i.e., blades) rotating within an enclosed chamber (i.e., casing). But in reality, this isn’t quite how it works! Instead:

The shaft turns the impeller – The shaft of your circulating pump will turn and rotate as you power on your unit; this rotates along with any other moving parts inside your unit’s casing such as gears, bearings, or seals (depending on what type of liquid is being pumped).

Is a circulating pump a centrifugal pump?

Circulator pump vs centrifugal pump

No, a circulating pump is not a centrifugal pump.

A circulating pump is a positive displacement pump and differs from a dynamic or centrifugal pump. A positive displacement pump includes the suction and discharge valves as part of the body of the pump. These valves are specially designed to provide minimal flow resistance when closed and maximum flow resistance when open, thus allowing both suction and discharge to occur at one time in each stroke cycle.

Dynamic pumps include no valves in their design; these types of pumps require an additional stroke element (or “piston”) that must be moved into position with each cycle in order to create suction or discharge conditions before moving on to its next position where it creates another cycle.

Lifespan.

A boiler circulating pump can last anywhere from a few months to several years. The life of a boiler circulator pump depends on the brand, model, and type of pump you have. If you are using a good quality pump that is well maintained, it can last up to 5 – 10 years. However, if you have purchased a cheap quality one it may only last 1 – 2 years as they quickly break down due to poor construction. Pumps that use a circulating system can be replaced before they break down, so there is no need to replace an entire heating system when your boiler circulator pump fails.

Where do you put a circulator pump on a boiler?

The location of the circulator pump on a boiler can vary depending on the specific design and configuration of the boiler system. However, there are a few common placements for circulator pumps in boiler systems:

- Integrated pump: Some modern boilers come with an integrated circulator pump. In this case, the pump is typically built into the boiler unit itself, usually near the heat exchanger. The exact location may vary depending on the specific boiler model.

- Near the boiler outlet: In many traditional boiler systems, the circulator pump is installed near the outlet of the boiler. This location allows the pump to push the hot water from the boiler into the heating distribution system, such as the radiators or baseboard heaters.

- On the return line: Another common placement is on the return line of the heating system. In this setup, the pump is installed on the pipe that brings the cooler water back from the heating system to the boiler for reheating. This location allows the pump to circulate the water effectively and maintain a consistent flow throughout the system.

How do I know if my boiler circulating pump is bad?

Circulator pump for the boiler not working

If you’re not sure whether or not your circulating pump needs to be replaced, there are a few ways to tell:

- The pump won’t turn on. If the pump doesn’t come on when the heating system switches on or cycles through its heating process, then this could be a sign that something is wrong with the circulator pump or wiring. You may need to replace or repair one or both of these things in order for your boiler to function properly again.

- The pump makes a loud noise. A loud screech or hum coming from the pump can mean that there’s something stuck inside of it—like debris—and this needs to be removed before further damage occurs.

- No heat circulation: If you notice that your radiators or baseboard heaters are not getting hot even though the boiler is running, it could be a sign of a faulty circulating pump.

- Leaks or drips: Check around the pump housing for any visible signs of water leakage or dripping. This can be a sign of a pump seal or gasket failure.

- Inconsistent heating: If some areas of your home are getting adequate heat while others remain cold, it could indicate a problem with the pump’s ability to distribute hot water evenly.

- Increased energy consumption: A malfunctioning pump may cause the boiler to work harder to maintain the desired temperature, resulting in higher energy bills.

- Overheating or excessive temperature rise: If the pump is not circulating water properly, it can cause the boiler to overheat, leading to safety concerns and potential damage.

- Pump failure warning light: Some boilers have a built-in indicator light that signals when the pump is not functioning correctly. Check your boiler’s manual to see if it has such a feature.

How much is a circulator pump for boiler?

Circulating pump price

The cost of a new circulating pump depends on the brand, model, and size. You can expect to spend between $200 and $800 for a new circulator pump, depending on what you want. The prices of the pumps vary according to their size and other features. Some pumps can be fitted with an automatic shutoff. The factors that affect the price include whether it’s an open-flow or closed-loop system, as well as if you want wireless connectivity enabled in your home automation system.

Conclusion.

Now you know how a circulating pump works and how much they cost to replace. If your boiler circulator pump is not working, don’t wait until it fails completely—call us today for service. We can help ensure that your replacement pump is installed correctly and will last for years without fail. If you want to know more about circulating pumps, please contact us: at +0086 186-2391-5479.

FAQs.

What is the purpose of a circulating pump?

A circulating pump serves a vital role in a boiler system by ensuring the consistent flow of hot water or steam to distribute heat evenly throughout your home, promoting comfort and efficiency.

Will boiler work without a circulating pump?

A boiler typically cannot operate effectively without a circulating pump, as it won't be able to circulate heated water or steam to the radiators or heating elements, leading to insufficient heating.

What are two types of circulating pumps?

There are two common types of circulating pumps: in-line pumps, which are installed directly within the piping, and circulator pumps, which attach to the boiler itself.

Where do you put the circulator pump on a boiler?

To position the circulator pump effectively on a boiler, it's usually placed on the return side, near the boiler's inlet, to facilitate the circulation of heated water back into the system.

How much does it cost to replace a circulating pump?

On average, The cost to replace a circulating pump ranges from $200 to $600, covering both parts and installation expenses. It can vary depending on factors such as pump type, brand, and labor costs.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies