The price of buying a steam generator is about $2,580 – 1,2500, depending on the size, model, brand, and other factors of the generator. Steam generators are used for the production of process steam in industries like chemicals, petrochemicals, power plants, and refineries. They produce heat and steam, which is distributed throughout the room through a network of pipes. They come in different sizes and shapes, but they all work in the same way. In this article, we’ll explain how generators work and how to choose one for your home or business.

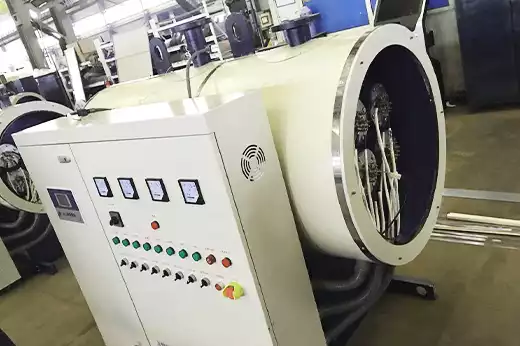

What is steam generator?

A steam generator is a device that produces steam, which can be used to heat water or in some cases produce electricity. The steam generated by it may be used in many different industries, including power generation and heating. In some cases, the steam is produced for its own sake; in others, it’s used to produce electricity from natural gas or other fuels. In many cases, these devices will also be referred to as boilers. They are used in many different industries, including:

- Power plants

- Chemical manufacturing facilities

- Biotechnology facilities

Steam boiler systems use either combustion or heat transfer (usually from another source) to create steam. The generated heat can then be used for various purposes. Boilers may provide hot water for residential or commercial use; they may be used in power plants to produce electricity, and they may even be part of industrial manufacturing processes for melting metals or curing rubber tires (among other things).

Working principle.

Steam generators are used to generate high-temperature steam from water. The steam is generated by heating the water in an enclosed container, which causes the molecules of water to move faster and collide with each other more often. This increases their kinetic energy, causing them to break apart into smaller pieces. These smaller pieces then combine with oxygen molecules in the air around them and form tiny bubbles of pure vapor (i.e., steam).

Typically, the process begins with water being heated by burning fossil fuels like coal or oil, which are then converted into pressurized gas that’s passed through a series of pipes called “tubes” (these tubes can be made out of metal or plastic). The resulting high pressure allows for more efficient heat transfer from one area to another—in this case, from the firebox where fuel burns into another chamber where water is located.

Lifespan.

The lifespan of a steam generator depends on the frequency of use, how often it is cleaned and maintained, and how well it is maintained.

For low-pressure unit or ones that do not return condensate to the boiler, that life expectancy may be extended by as much as 5 years. The typical life expectancy for a high-pressure steam generator with a condensate return system would be around 10 years.

If you use your generator frequently, the unit should last between 5 and 10 years. When you use your product less frequently, the lifespan will be extended to as much as 15 years. Maintaining your generator properly can also increase its longevity by up to 50%.

Pros & Cons.

Pros:

- Steam generators are more efficient than boilers. This means that they produce a higher level of heat at a lower cost, which makes them a great choice for commercial spaces or large families. If you have a steam-powered plant, it will run at 100% efficiency all the time, while a boiler can only achieve that level of efficiency when there’s enough demand for hot water.

- They don’t require electricity to run—just natural gas or propane fuel. This makes them ideal for remote locations where there isn’t access to electricity or as backup sources in case of an outage.

- Steam generators are more energy efficient than boilers, as you can use more steam per pound of water.

- They’re also smaller and lighter than boilers and do not require a boiler room to be installed in your home.

- The system is easy to install, making it ideal for DIY-ers who have some experience with plumbing projects but not much plumbing experience.

Cons

- Steam generators cost about $4–5 per hour of heat, depending on the size and brand of your generator unit. Generators must be kept clean and serviced regularly to ensure they’re operating safely and efficiently. You may have difficulty finding technicians trained on how they work (although this is becoming less true as more people use these types of systems).

What are steam generators used for?

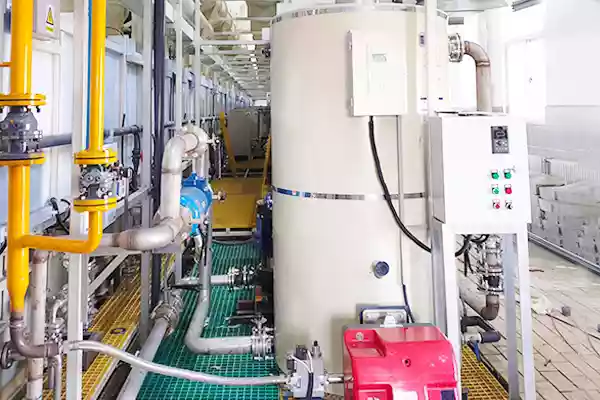

Steam generators are used in power plants, manufacturing facilities, food and beverage production plants, chemical manufacturing operations, pharmaceutical manufacturing facilities, and other industrial applications. Industrial steam generators can be found in many places where heat is needed for processing or generating power.

In power plants, generators are used to convert the heat of burning fossil fuels into electricity.

In manufacturing facilities, they are used to produce high-pressure steam that is injected into a process chamber (for instance: injection molding machines) to provide heating and pressurization of fluids or gasses within the process chamber.

In the food and beverage industry, steam generators are used to cook food and make beverages.

Boiler vs steam generator.

A boiler and a steam generator are both devices used to generate steam, but there are some differences between them in terms of their design, operation, and application. Here’s an overview of the key distinctions:

Design and Construction.

Boiler: A boiler is a closed vessel that contains water or other fluid, which is heated to produce steam. It typically consists of a shell, tubes, or passages for the flow of hot gases or combustion products and a heat source such as a furnace or burner.

Steam Generator: A steam generator, also known as a steam boiler or a heat exchanger, is a device that uses heat energy to convert water into steam without the presence of combustion gases. It usually consists of coils or tubes through which water circulates, while a separate heat source (such as burning fuel or electric heating elements) transfers heat to the water.

Heat Source.

Boiler: In a boiler, heat is usually generated through the combustion of fossil fuels (such as coal, oil, or natural gas) or a nuclear reaction. The combustion gases pass through the boiler tubes, transferring their heat energy to the water.

Steam Generator: They can be heated by various means, including fossil fuels, nuclear energy, solar energy, or electricity. The heat source is external to the water-containing tubes, and the transfer of heat occurs through conduction.

Operating Pressure and Temperature.

Boiler: Boilers are designed to operate at high pressures and temperatures. The steam produced in a boiler is often used for power generation, heating systems, industrial processes, or other applications where high-pressure steam is required.

Steam Generator: They can operate at lower pressures and temperatures compared to boilers. They are commonly used in applications such as small-scale power generation, steam cleaning, sterilization, or humidification.

Safety Regulations.

Boiler: Boilers are subject to various safety regulations and codes due to the high pressures and temperatures involved. These regulations include guidelines for construction, operation, maintenance, and inspection to ensure safety.

Steam Generator: Steam generators, especially those with lower operating pressures, may have different safety regulations and requirements compared to boilers. The specific safety standards depend on the intended application and local regulations.

What size steam generator do I need?

The size of your steam generator will depend on the amount of steam you need. If you are going to be steaming large amounts, then a larger unit would be more appropriate. If the number of people using it will be smaller in number, then a smaller model would suffice. You can determine the size of your generator by multiplying the number of people who will be using it by the number of square feet you need to cover, then add 50%.

To calculate how much space is needed, here is an example:

100 square feet = 100 feet x 100 feet = 10,000 square inches

For example, if you have a studio apartment that you’re looking to heat and another person will be living with you, a 10,000 square foot space would require a 150-200 kW (kilowatt) steam generator. The size of the generator also depends on how many rooms or areas in your home need heating.

Steam shower generator installation.

Step 1: Gather Tools and Materials

Before you start, make sure you have all the necessary tools and materials at hand:

Steam shower generator kit

Power drill

Screwdrivers

Pipe wrench

Copper or PVC pipes and fittings

Teflon tape

Electrical wiring and connectors

Level

Hammer

Silicone sealant

Safety goggles and gloves

Step 2: Choose a Suitable Location

Select a location for the steam shower generator unit. Preferably within 25 to 30 feet of the steam shower enclosure. It should be easily accessible for maintenance and close to a water source and electrical outlet.

Step 3: Prepare the Area

Clear the area and ensure it’s clean and free from any obstructions. Place a stable platform or surface to keep the unit elevated and away from potential water exposure.

Step 4: Install Water Supply and Drainage

Connect the water supply to the steam shower generator using appropriate pipes and fittings. Make sure to use Teflon tape on threaded connections to prevent leaks. If your unit has a drainage system, connect it as well.

Step 5: Mount the Generator Unit

Place the unit on the platform you prepared earlier. Use a level to ensure it’s properly balanced. You might need to secure it using screws or brackets, depending on the unit’s design.

Step 6: Connect Steam Outlet to Shower Enclosure

Attach the steam outlet pipe to the steam nozzle on the generator unit. Run the pipe to your shower enclosure and secure it in place, ensuring there are no kinks or sharp bends.

Step 7: Electrical Wiring

If you’re comfortable with electrical work, connect the power supply to the generator according to the manufacturer’s instructions. If not, it’s best to hire a licensed electrician for this step to ensure safety.

Step 8: Ventilation

Steam shower generators produce a significant amount of heat and moisture. Ensure proper ventilation in the shower enclosure to prevent excess humidity buildup. This might involve installing exhaust fans or vents.

Step 9: Test Run

Fill the steam generator with water as per the manufacturer’s instructions. Turn it on and let it run to ensure it’s producing steam properly and that there are no leaks.

Step 10: Seal and Finish

Seal any gaps around pipes, fittings, and the generator unit itself using silicone sealant. This helps prevent water from getting into places it shouldn’t be.

Step 11: Final Check

Double-check all connections, both water and electrical, to ensure everything is secure and properly connected.

Step 12: Enjoy Your Steam Shower

Once everything is in place and you’re satisfied with the installation, you’re ready to enjoy the comfort of your new steam shower!

How much is a steam generator?

A steam generator can cost from $2,580 to $12,500. This price is dependent on the size of the unit and the brand of generator you choose. The price of a steam generator is also dependent on how much water it can hold. For example, if you have several bathrooms that need cleaning and each bathroom has its own shower/tub area, then purchasing a larger capacity generator would be beneficial because they generally hold more water than smaller models.

- A small unit (1-2 bathrooms) will typically cost anywhere from $2,500-$5,000

- A larger unit (3+ bathrooms) can range between $6,000 to $12,000

A lot of factors come into play when determining how much a steam generator costs:

- The size of your home’s hot water system (the tank)

- Whether or not you want to convert from electric heating to gas heating

Conclusion

Steam generators are used in various industries to produce steam from water. They can be used for commercial or industrial purposes. Steam is used in many processes within these industries, and the generator process provides hot water at different temperatures which can be regulated by changing the pressure of incoming water in order to heat it up quickly without using electricity or other fuels.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies