Introduction

Wanting to install a steam boiler is a complicated process. However, if you are skilled and have the right equipment, it can be an easy task. In this guide, we’ll discuss how you can install your own steam boiler. And some things to consider before installing one in your home or commercial building. We’ll also look at how much it costs to install one yourself vs hiring professional help!

Choose a Suitable Installation Location

You need to choose a suitable location for your steam boiler installation. The space should be large enough to accommodate the boiler, but not so large that it will waste energy by allowing heat to escape. Here are some things to keep in mind:

- It should also be level, dry, and well-ventilated.

- Away from combustible materials such as wood or paper.

- Accessible for maintenance and repair.

- A safe distance from other buildings, equipment, or obstructions.

- Not in an area where water could flow into the boiler room.

Flue Installation

When installing your steam boiler, you will need to make sure that the flue is installed correctly. The location of the flue can be determined by several factors:

The height at which it should be placed will depend on how high above ground level or water level it needs to be. You’ll want to make sure that there is enough clearance from any nearby structures or objects so that hot gases can safely vent away from them without causing damage or injury.

You should use materials that are designed specifically for use with boilers like PVC piping and galvanized steel pipes because these materials resist corrosion better than others do over time.

Once you’ve determined the location of your steam boiler and flue, it’s time to install them. The first thing to do is measure and cut the flue pipe according to the length required by your building code and local regulations.

Once you have cut all of your materials, it’s time to start assembling them together. First, attach one end (or both) of a 90-degree elbow onto either side of the back plate that comes with most boilers. So they can rest securely against each other when installed inside an enclosure or wall opening. Then take another section from that same package labeled “Flue Pipe Assembly” or something similar. This will be used as support material between two elbows. This helps stabilize airflow within chimney walls!

The next step attaching sections together using clamps provided by the manufacturer which makes sure everything stays put firmly. Without falling apart under pressure applied by wind blowing through open doorways nearby windows etcetera.

Gas Train Design

The gas train design is the arrangement of burners, valves, and controls. It’s important because it affects how your boiler operates and how much maintenance you need to do on a regular basis. The size of your boiler will determine what type of gas train design you need to use.

The most common types of gas trains are:

- Single-stage: One main burner with a secondary air supply through an air pre-heater or blower.

- Two-stage: Two main burners with a secondary air supply through an air pre-heater or blower.

- Three-stage: Three main burners with a secondary air supply through an air pre-heater or blower.

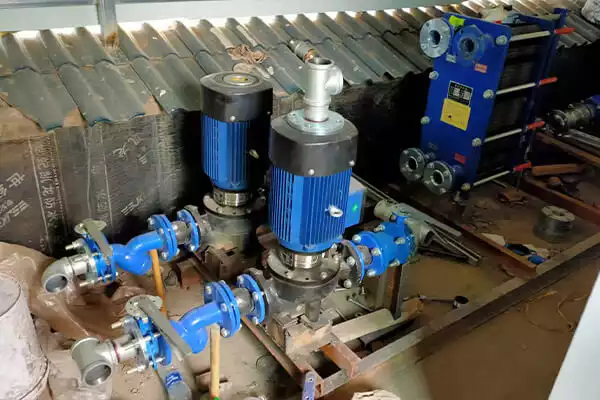

Piping and Valves

In addition to the boiler, you will need piping and valves. The piping should be made of stainless steel so that it can withstand high temperatures without corroding or rusting. You should also use ball valves for your system. Ball valves are designed for high-pressure applications, and they’re rated for various conditions such as temperature and material types (such as copper or brass).

You’ll also want to make sure that all materials used are compatible with one another. For instance, you wouldn’t want brass fittings connecting copper pipes together. Because they would corrode over time due to their different chemical compositions!

Safety Controls

Safety controls should be installed in the steam boiler. Safety valves, pressure safety switches, and high-temperature limit switches are used to protect the boiler against excessive pressure.

Pressure safety valves are used to protect the boiler against excessive pressure by venting steam through a relief valve at a preset pressure. Pressure safety switches can be set up so that they activate when there is too much pressure in your system. And will shut off the power supply until repairs have been made or pressure has been reduced below design limits set by code requirements (usually 15 PSIG). High-temperature limit switches also monitor temperatures inside your system to ensure the safe operation of all components within it.

Attaching the Gas Line

Once you have connected the water line, it is time to connect your gas line. To do this, turn off all electrical power to your boiler and then disconnect any existing gas lines from inside of it. You should also shut off any pilot lights located on top of or near your new steam boiler before proceeding further with this step in order to prevent unnecessary accidents while working on it.

After disconnecting any existing pipes that were connected before you purchased your new steam boiler, place them aside so they don’t get lost during installation (you may want them later). Next, attach one end of a new flexible copper tubing to either side of an expansion joint fitting by twisting clockwise until tight. Then repeat this process with another fitting until both ends are securely fastened together with two fittings apiece (you will need four total).

Combustion Tuning

Combustion tuning is an important step in the installation process. It ensures that your boiler is operating at maximum efficiency, which will improve its lifespan and reduce its carbon footprint.

To ensure that you’re not over-firing your boiler, take note of how much steam is being produced and compare this to how much heat energy is being used. If there’s more steam than heat energy being used by the building then it means that either:

- Your insulation isn’t up to scratch (and therefore some of that heat is escaping through walls etc) or.

- There may be something wrong with your system – maybe there isn’t enough water being pumped through?

Feed and Return Pipes

Now that you have the boiler installed, it’s time to connect the feed and return pipes. These are the pipes that connect your steam boiler to your main water supply. The feed pipe brings water from your main supply into the boiler while the return takes it back out again.

The first thing you need to do is determine where these two lines are going to be located on your property so they can be connected properly later on when it comes time for the installation of other components such as radiators or heating systems.

Blowdown Receiver

The blowdown receiver is used to collect the condensate and blowdown. It is usually located below the steam boiler, but can also be installed above it, depending on your preference. The blowdown receiver is connected to the steam boiler via a discharge pipe that runs from one side of a horizontal or vertical shell. Through an opening in its bottom, up through another opening in its top (or side). Where it connects with a discharge line leading away from your home’s foundation or basement walls.

The blowdown receiver should also be connected to your condensate pump via another discharge line running horizontally across this same opening on top (or side) of this device as well. This way you won’t have any problems getting rid of all those nasty contaminants!

Water Treatment Equipment

Water treatment equipment is essential to ensure that your steam boiler operates at peak performance, efficiency, and safety. The water treatment equipment should be installed before or after the installation of the steam boiler depending on your preference.

- Pre-treatment: If you want to install pre-treatment facilities such as a filter, softener, or water softener then this should be done first.

- Post Treatment: If you want to install post-treatment facilities such as an ultraviolet lamp then this should be done after installing all other components of your system like piping etcetera.

Start it Up

Before starting the steam boiler, you need to reconfirm the following 4 things:

Set your controls. Make sure that the controls are set to run at low temperatures (around 50 C) and high pressures (around 10 bar).

Check that the flue is clear. If there are any obstructions in or near your chimney, this could cause an explosion when you light up your new boiler–so take care!

Check that your water treatment equipment is working properly and treating incoming water at its proper level of hardness (if applicable). If not, get it fixed immediately!

Finally, make sure you have enough water in your tank before starting up a boiler for the first time. You’ll want at least 1/2 inch (1 cm) above what’s recommended by your manufacturer so as not to damage any parts inside when they heat up during startup.

Installation Cost

The cost of installing a steam boiler will vary depending on the size and complexity of your system, but it’s generally between $1,200 and $6,500. To get an estimate for your specific project, it’s best to speak with a local HVAC contractor. They can come out and inspect your home before giving you an exact price quote.

You can save money by doing some research before hiring an installer. You should know what kind of boiler you want to be installed in your home before calling around for estimates. The table below shows the cost of installing a steam boiler by size, type and fuel used:

| Boiler Size | Type | Fuel | Cost (USD) |

|---|---|---|---|

| 100 HP | Firetube | Natural Gas | $1,200 |

| Watertube | Natural Gas | $2,000 | |

| Firetube | Oil | $1,800 | |

| Watertube | Oil | $2,200 | |

| 200 HP | Firetube | Natural Gas | $2,500 |

| Watertube | Natural Gas | $3,000 | |

| Firetube | Oil | $2,800 | |

| Watertube | Oil | $3,200 | |

| 500 HP | Firetube | Natural Gas | $5,000 |

| Watertube | Natural Gas | $6,000 | |

| Firetube | Oil | $5,500 | |

| Watertube | Oil | $6,500 |

Conclusion

The installation of a steam boiler is a complex process that requires several steps to be taken. If you are planning on installing one for your home or business, we recommend hiring an experienced contractor who can help guide you through this process. If you want to learn about the details of installing a steam boiler, please contact us at +0086 186-2391-5479.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies