Currently, our company portfolio boasts over 100 patented technologies, with a firm grasp on the pivotal advancements in clean fuel boiler technology. Our prowess in research, development, and production places us at the forefront of the industry.

We rely on its own technical advantages in boilers. And digital control, boiler remote monitoring cloud service platform has been organized. It has genuinely realized the intelligent operating system of boilers. And the operation of boilers is more convenient and faster.

Provide you with more efficient and energy-saving boiler equipment.

QUICK QUOTATION

At present, We have more than 100 patented technologies and obtained the national technology patent certificate.

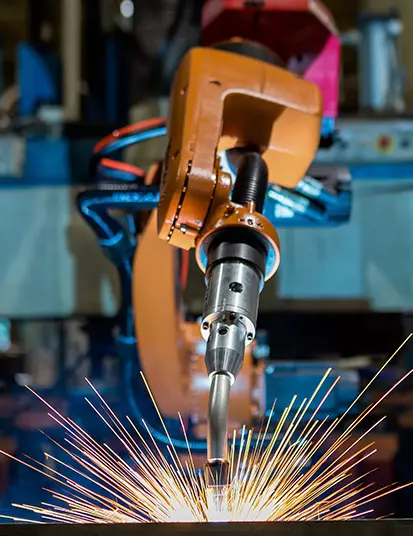

In order to produce higher-quality boiler equipment. We have carried out a large-scale welding revolution. Eliminating the traditional manual welding operations with low efficiency, low precision, and poor stability. The mechanical welding equipment for automatic operation mode. We've introduced automated welding processes across all vital components, spanning from the drum to the tube sheet. Notably, our submerged arc welding, argon arc welding, and carbon dioxide-shielded welding techniques have undergone intelligent refinements for improved precision.

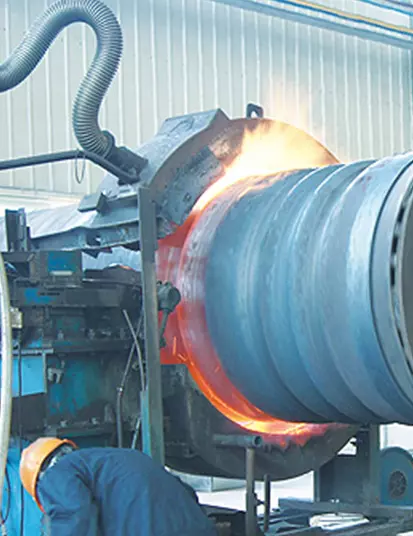

Learn MoreA point of distinctiveness lies in our proprietary processing technique employed in boiler fabrication. The corrugated furnace generated through this production line serves a dual purpose. Not only does it expand the boiler's heating surface, but it also mitigates the detrimental mental effects of thermal expansion and contraction on the combustion chamber. Therefore, not only the heating efficiency of the boiler is improved, but also its service life is extended.

Learn MoreOur integration of drilling processes has yielded parts and components of elevated precision due to digitalization. This precision serves as the bedrock for ensuring the quality of boiler welding and assembly. Our Boiler has introduced advanced numerical control and digital equipment. These include a high-speed CNC plane drill, CNC drum drill, and 3D laser cutting machine. Our robust infrastructure comprises 600 sets of 4-axis CNC pipe bending machines, Φ168 CNC three-dimensional pipe bending equipment, a 100mm three-roller CNC universal plate rolling machine, as well as specialized production lines for serpentine pipes, and coiled pipes.

Learn MoreOur Ultraten technology is a novel heat exchange element. Our Ultraten technology is a novel heat exchange element. It features wing tubes designed for optimum energy efficiency. This cutting-edge condensation technology facilitates the judicious utilization of energy by rapidly cooling flue gases. This innovation not only conserves energy but also operation efficiency.

Learn MoreOur flue gas condensation waste heat recovery device spiral finned tube is used as the heating surface. It has high heat exchange efficiency and sufficient heating surface. And low resistance of the flue gas side system, which meets the requirements of ordinary burners.

Learn MoreTo address nitrogen oxide emissions, we've implemented Flue Gas Recirculation (FGR) technology. This technique involves recirculating a portion of the flue gas, usually accounting for 5-20% of total exhaust. It can effectively curb nitrogen oxide production by a margin of 10-90%.

Learn More

The client is a large-scale food processing company based in Belarus, specializing in the production of canned vegetables and fruits. Their manufacturing process requires a steady and efficient supply of steam for sterilization, cooking, and packaging. After evaluating the client’s requirements, we recommended a fully automated, natural gas-fired 10-ton steam boiler.

We provide you with sales sources, overall factory delivery, on-site service, and maintenance for boilers and boiler room equipment.

Send Inquiry

2025-05-09

2025-02-07

2024-12-26

We developed for many years based on quality and have obtained a number of authoritative quality certifications.