Introduction

A low water cut-off boiler is a boiler that automatically shuts off when it runs out of water. It’s a safety feature that prevents the possibility of an explosion or fire due to dry conditions in the water tank. There are different types of low-water cutoff boilers, and they have their own advantages and disadvantages. We will learn it in more detail in this article.

What is a low water cutoff on a boiler?

A low water cut-off in a boiler is a device that protects the boiler by preventing it from operating when the water level falls below a set safe level. If your boiler has one, it should be installed in the same area as your pressure relief valve, which acts as another safeguard against excessive pressure build-up.

A low water cutoff is also known as a pressure relief valve (PRV). It’s designed to release steam if there isn’t enough liquid inside the heating system to keep up with the demand for hot water or heat generation.

Does a boiler need a low water cutoff?

A boiler needs a low water cutoff. When you turn on a boiler, it heats up and expands as it turns into steam. This means that if there isn’t enough water in the system to accommodate this expansion, it can cause damage to internal components. A low water cutoff helps prevent this by shutting off power when there isn’t enough liquid available for proper function. Thus protecting your home’s heating system from possible damage or failure.

If you have an electric boiler, then there’s no need for this safety feature since they don’t use any kind of flammable liquid or gas as fuel. But if yours is powered by oil or gas then it will require this additional piece of equipment.

A low water cutoff is an important safety feature that helps protect your home and family from fire hazards. If the temperature inside your boiler gets too high, it will automatically shut off to prevent damage or injury.

What does a low water cut-off valve do?

A low water cut-off valve is a device that shuts off the fuel supply to your boiler when there’s insufficient water in your heating system. It is used to prevent damage to your heating system and boiler. It shuts off the fuel supply to the boiler when there is not enough water in its reservoir, preventing it from running dry. This prevents damage to both your heating system and boiler, which could cost you thousands of dollars in repairs or replacements.

What type of LWCO do I need?

There are two types of LWCOs: thermostatic and pressure.

The thermostatic type is typically used on boilers that are not equipped with a circulator, such as a direct-fired boiler or an indirect hot water heater. This type of LWCO can detect when there is too much water in the system and will shut off the burner automatically if it senses there is no more need for heat output from the boiler.

The pressure-type LWCO is used on boilers that have a circulator, which means they’re circulating water through them constantly (like most residential heating systems). Pressure-type LWCOS work by detecting fluctuations in pressure within your pipes due to changes in temperature or flow rate. Which signals them to open or close accordingly so as not to overheat pipes or cause other problems!

How do I install a low water cut off in my boiler?

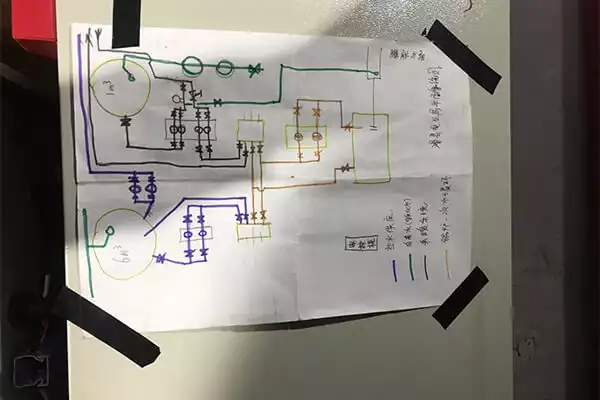

Low water cut off installation

To install a low water cut-off in your boiler, you can refer to the following steps:

First, you need to remove the old one. You can do this by shutting off the power supply and turning off any pilot lights that may be on.

Next, disconnect all of the wires from their respective terminals on both sides of your boiler and then remove them entirely from their corresponding places inside of it (you should have four total).

Then, once removed, unscrew each bolt securing both sides together by hand. Do not use tools as they may damage other parts inside your unit when removed later.

Finally, pull apart these two pieces carefully so that they don’t damage each other while doing so or break any internal components.

How often should low water cutoff be tested?

It’s important to test your low water cutoff regularly so that you can be sure it will work when there’s a real emergency. You should test it every year, or at least once every six months. If you don’t have the time or money to test it yourself, ask an expert who works on boilers for advice on how often they recommend testing low-water cutoffs.

How do I test a low-water cut-off probe?

Test low water cut off boiler

To test a Low Water Cut-Off Probe, turn off the power to your boiler. Open up the access door and remove the low water cut-off probe from its mounting bracket. Connect a multimeter to one of its terminals, then check for continuity with another terminal on the probe itself (you may need to use different probes depending on what type you have). If there is no continuity between these two points, replace your low water cutoff immediately as this indicates that it needs replacement

Connect a multimeter to one end of it, then check for continuity by pressing down on the button on top of your multimeter (if you don’t know how to do this, call an electrician). If there is no continuity, replace it!

How do I troubleshoot low water cut off?

- Check the water level in the boiler. If it is low, then you will need to refill it.

- Check your pressure switch for signs of damage or corrosion. If there are any, replace it with a new one.

- Make sure that there are no air gaps between piping and fittings as this can cause reduced flow rates and affect the operation of pumps and other components.

- Ensure that all electrical connections are tightly secured before starting up again (you may want to use some thread sealant tape).

Conclusion

In conclusion, low water cut-off boilers are a great way to keep your home warm and safe. They’re easy to install, require little maintenance and come in a variety of styles. If you want to learn about the details of it, please contact us at +0086 186-2391-5479.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies