The Cheap Fire Tube Boiler Cost – Fire Tube Boiler

The price of a fire tube boiler is about $3,600 – $12,000. A fire tube boiler is a type of boiler in which water partially fills a heated vessel and transfers heat to the surrounding air, which then passes through one or more flues to the chimney. The heated water vaporizes, creating a vacuum that draws fresh air into the combustion chamber. As the hot gases rise up through this additional venting system, they cool and deposit their heat into the room’s atmosphere before reaching the top of the chimney.

What is a fire tube boiler used for?

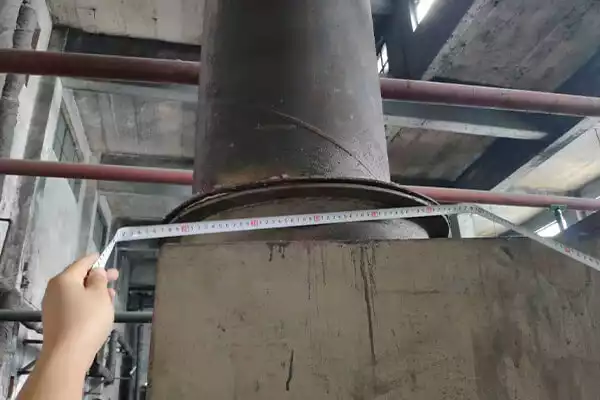

Firetube boiler

Fire tube boilers are used for steam generation, power generation, heating, cooking, water heating, and process heating. They have been used in industrial settings since the 1800s to provide energy to machinery and equipment.

A fire tube boiler, also known as a vertical boiler, is used for a variety of applications, including the generation of steam. The design of a fire tube vertical boiler consists of multiple cylindrical water-filled tubes connected to an exterior shell and enclosed in an outer layer. This allows for more heat transfer and minimizes corrosion while maximizing efficiency over other types of boilers.

Get an online fixed price in 20 seconds:

How does a fire tube boiler work?

How a fire tube boiler works

A fire tube boiler is a type of boiler where water is heated by the fire in tubes. The steam produced by this process turns into electricity which powers machinery.

The fire tube boiler works as follows:

- Water is pumped into the bottom of a cylindrical container called a ‘firebox’ and fed through one or more vertical tubes set horizontally within it. A gate separates the water from the combustion chamber above, where fuel (typically coal) burns and heats up the air that rises into this chamber. At the top of these tubes, some of this hot air mixes with cold water from an external pipe before returning to be reheated in another pass down through more tubes; this process continues until enough heat has been transferred for all of it to exit at full temperature via an outlet near ground level (or below).

What is the type of fire tube boiler?

Fire tube boiler example

Fire tube boilers are a type of water-tube boiler in which hot gases pass through multiple tubes, heating the water inside. There are two types of fire-tube boilers: single-pass and multi-pass.

Single-pass firetube boilers feature one set of tubes that heat the water throughout its length; these tend to be more efficient than multi-pass boilers because less energy is wasted heating areas that aren’t used for generating steam.

Multi-pass firetube boilers have multiple sets of tubes running parallel to each other; this allows them to generate steam from both ends at once, improving efficiency even further, as well as increasing their output by reducing backpressure on the furnace or flue gas ductwork.

There are two types of fire tube boilers: direct-acting and indirect-acting (also called cross-flow). In direct-acting fire-tube boilers, the furnace gases enter the combustion chamber at its upper end and then flow downward directly into the air space between the tubes. In indirect-acting fire-tube boilers, they enter at one end and travel upward through an annulus between two concentric tubes before reaching their destination.

Looking for boilers with sophisticated manufacturing, and great quality?

Fangkuai boiler can always provide what you want.

What is the difference between fire tube boiler and water tube boiler?

Fire tube boiler vs water tube

The difference between a fire tube boiler and a water tube boiler is that they are used for different purposes.

- Fire tube boiler

Fire-tube boilers are used for heating and power generation. They have a large surface area. When air is heated, the hot air rises up through the furnace tubes and passes through a series of flues that lead to an exhaust stack. The water from the bottom of each tube is returned to the top of its respective tube where it circulates down again in counterflow to absorb heat from the steam generated by combustion. The fuel used for firing fire tube boilers includes coke, coal, and natural gas.

- Water Tube Boiler

A water tube boiler has a small surface area compared with a firetube boiler which means that they need low-pressure steam (less than 3 bar) to operate properly; otherwise, they will not get enough oxygen into their tubes which can lead to corrosion problems inside these narrow tubes over time if they’re not properly maintained with chemicals like sodium chloride (salt).

What fire tube boiler is most efficient?

Fire tube boiler efficiency

A fire tube boiler is most efficient when the ratio of heating surface to volume is increased. This can be done by increasing the number of tubes, or by using longer and/or wider tubes. This will increase the amount of heated fluid that flows through each tube so that more heat can be transferred from one end to another without being lost through radiation and convection.

Another way to improve efficiency is by increasing both the ratio of heating surface to weight (which means making it thinner) and increasing its width. Since a firetube boiler’s main function is to convert water into steam via heat transfer, they should be designed with as much surface area as possible so that more heat can be transferred into them (and out again).

Get FREE Boiler Quotes

- ✔Get FREE Local Boiler Quotes Today

- ✔Compare The Best Prices

- ✔Save Money On Your New Boiler Today!

How much is a fire tube boiler?

Fire tube boiler cost

The cost of fire tube boilers depends on the size, type, and material. The most efficient fire-tube boiler is a water-tube boiler. They are available in different sizes to suit your needs and requirements. If you want to reduce the cost of buying a firetube boiler, then you can choose a smaller version that will save you money on installation costs but still meet your heating needs.

The cost of a fire tube boiler can be calculated by using the following formula:

Cost = (Average Cost x Capacity in kilowatts) + ($10,000 for every 1000 liters)

The cost of buying a custom-built fire-tube boiler can be reduced by using a smaller size that fits your budget better but still meets your needs for heating needs in terms of output temperature ranges needed at different times throughout each year so you don’t have to pay extra money just because one particular season might need something different from what another time period would require over again when it comes down to operating costs related specifically toward heating needs instead.

Conclusion

A fire tube boiler is a type of boiler that uses a heat exchanger to transfer heat from the combustion chamber to water in the firebox. It can be used as either a primary or secondary heating system. These boilers are often used in industrial settings where they require high temperatures and pressures. If you want to know more about fire tube boilers, please contact us: at +0086 186-2391-5479.

Looking for boilers with sophisticated manufacturing, and great quality?

Fangkuai boiler can always provide what you want.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies