The Best Boiler Deaerator System in 2022 – Deaerator Working Principle

A boiler deaerator is a device that removes oxygen from water in order to increase the efficiency of boilers. It also reduces the risk of corrosion in pipes and tanks, as well as allows for the use of less-expensive fuels such as natural gas. When air is removed from the steam, it increases its purity and decreases its moisture content which results in higher efficiency and output of boilers with no loss of pressure or water quality of service water supply.

What is the deaerator in a boiler?

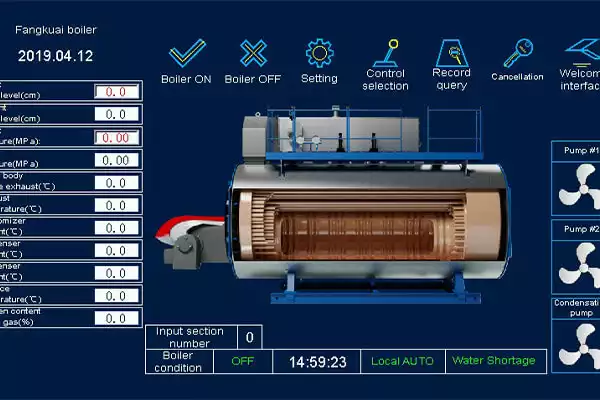

Boiler deaerator system

A boiler deaerator is a device used in boilers to remove air from the steam. It is used to prevent corrosion and scaling of boiler tubes, reduce the amount of water required to produce steam, and it also helps in improving efficiency by reducing thermal shock.

The main function of deaerators are:

- Remove entrained air from the water before it enters into a boiler or condenser system.

- Eliminate scale formation inside the tubes by removing dissolved oxygen with high-intensity agitation (high temperature) which reduces corrosion rates.

Get an online fixed price in 20 seconds:

What does a boiler deaerator do?

Boiler deaerator working

In a boiler, the deaerator removes air from the water before it is converted to steam. The purpose of removing air from water is to prevent the foaming of the liquid. Air bubbles in a boiler may break free during operation and cause damage to components by becoming trapped within them or blocking flow channels.

In power plants, boilers are used for steam production and are often fitted with deaerators as a safety measure. Deaerators make up an important part of the safety systems for many industrial facilities because they remove oxygen from process fluids before these fluids enter pipes that could otherwise corrode if exposed too long to oxygenated liquids (such as natural gas).

How does a boiler deaerator work?

Boiler deaerator working principle

A boiler deaerator is a device that removes air from the water in the boiler. It is a cylindrical vessel that is installed in the boiler and has a number of holes on its bottom, through which water enters. As water enters through these holes, air bubbles are forced out. This allows for more efficient combustion, so you can save money on fuel costs by using less fuel to heat your home or business building.

A typical boiler deaerator will have two compartments inside: one larger compartment which holds hot water from the burner and one smaller compartment where fresh cold water mixes with heated hot water before being fed back into the system for re-heating. The fresh cold supply line passes through an opening at the top of this second chamber where it mixes with heated hot liquid from below before entering back into circulation via another opening at its bottom edge near ground level (see diagram).

Need a new boiler deaerators?

How long does the boiler deaerator last?

Boiler deaerator lifespan

Boiler deaerators are made from stainless steel, which is a very durable material. As such, you can expect your deaerator to last for up to 15 years.

The deaerator is a very useful device that will help you save money on fuel costs. It also makes sure that no harmful substances enter your home or business as well as protects the environment by removing any excess moisture from the water in your boiler system.

Boiler deaerators are easy to install and require no special tools or knowledge.

Why deaerator is used in a boiler?

Boiler deaerator function

The deaerator is used to remove air from boiler feed water, prevent water hammer, and remove air bubbles. Deaerators are commonly used in power plants due to their ability to remove entrained gases from the feedwater and provide a more stable environment for heat transfer.

The deaerator is used to remove air from the feed water and to prevent the water hammer. A water hammer is a sudden pressure drop in the steam system, caused by the closing of an isolation valve or other means while there is still steam in the line. This results in a sharp slug of water leaving the deaerator, which can cause damage to equipment downstream. The deaerator also provides a method for removing entrained air and other gases from boiler feedwater in order that they do not reach your process.

Get FREE Boiler Deaerators Quotes

- ✔Get FREE Local Deaerators Quotes Today

- ✔Compare The Best Prices

- ✔Save Money On Your New Deaerators Today!

How much does it cost to buy a boiler deaerator?

Boiler deaerator price

If you’re looking to purchase a brand-new boiler deaerator, they can be pretty costly. New ones come in at around $1,000 or more depending on their size and material. The cost of buying a boiler deaerator will depend on the size of your boiler and whether you want to buy a used one or a new one.

If you’re looking for something specific, like a stainless steel deaerator, then it’s going to be more expensive than if you were just looking for any old deaerator. If you’re on a budget and don’t mind buying an older model that might not work as well as the latest models, then there are plenty of options available at lower prices.

Conclusion

A boiler deaerator can be used for heating water, cooling water, and purifying water. When it comes to deaerators for heating or cooling water, there are no significant differences in the way they work. It is important to note that deaerators are not designed to remove all impurities from your water but only those that have a high solubility in H2O such as CO2. If you want to know more about boiler deaerator, please contact us: +0086 186-2391-5479.

Looking for boiler deaerators with sophisticated manufacturing, and great quality?

Fangkuai boiler can always provide what you want.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies