Perkenalan

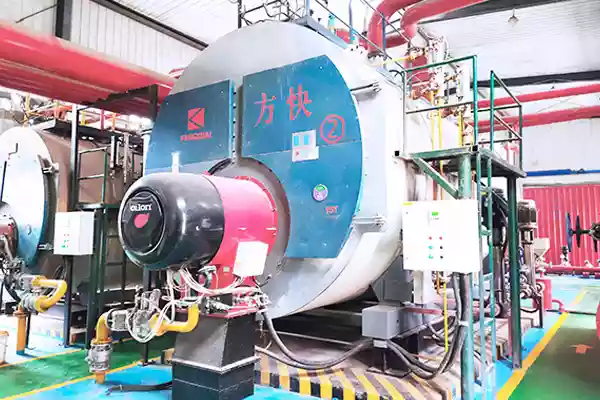

Boiler panas limbah adalah cara yang bagus bagi perusahaan untuk meningkatkan efisiensi energi mereka dan mengurangi biaya pemanasan dan pendinginan. Mereka dapat digunakan untuk memulihkan panas limbah dari proses industri dan mengubahnya menjadi uap yang dapat digunakan untuk sistem panas. Boiler panas limbah dapat digunakan di beberapa industri yang berbeda termasuk kimia, bahan kimia minyak bumi, minyak dan gas, makanan, Dan Industri minuman. Dalam artikel ini, Anda akan mempelajari semua tentang itu. Sehingga Anda dapat membuat pilihan terbaik.

Mengapa buang air panas digunakan?

Mengurangi konsumsi energi. Buang panas boiler mengurangi jumlah energi yang Anda gunakan untuk memanaskan bangunan dan air dengan menangkap sisa panas dari proses industri dan memindahkannya ke fasilitas Anda.

Kurangi gas rumah kaca. Boiler panas limbah dapat membantu Anda mencapai sertifikasi LEED, serta memenuhi persyaratan EPA untuk mengurangi emisi ke atmosfer dengan menangkap karbon dioksida (CO2) dan polutan berbahaya lainnya yang diciptakan dengan membakar bahan bakar fosil seperti batubara atau gas alam untuk menghasilkan listrik.

Meningkatkan efisiensi dengan menggunakan lebih sedikit bahan bakar secara keseluruhan. Saat digunakan bersama dengan sistem boiler yang ada, Sistem pemulihan panas limbah akan meningkatkan efisiensi dan mengurangi biaya operasi karena mengurangi permintaan untuk pembelian bahan bakar sementara juga meningkatkan kinerja keseluruhan pada suhu yang lebih rendah daripada tungku tradisional saja yang dapat disediakan sendiri.

Apa itu boiler panas limbah?

Boiler panas limbah menggunakan panas buang dari suatu proses untuk menghasilkan uap, yang digunakan dalam turbin uap untuk menghasilkan listrik. Keuntungan dari jenis sistem ini dibandingkan jenis pembangkit listrik lainnya adalah tidak memerlukannya konsumsi bahan bakar tambahan atau emisi CO2 dari pembakaran bahan bakar fosil.

Selain itu, karena boiler limbah panas sering digunakan sebagai bagian dari proses industri yang ada (seperti produksi baja), mereka dapat dipasang tanpa biaya modal yang signifikan atau perubahan dalam proses manufaktur itu sendiri.

Apakah boiler panas limbah penukar panas?

Boiler limbah panas adalah penukar panas. Penukar panas mentransfer panas dari satu media ke media lainnya. Pada kasus ini, sumber suhu rendah biasanya air yang telah dipanaskan oleh proses industri seperti pembangkit listrik atau manufaktur kimia. Sumber suhu tinggi dapat berupa uap yang dihasilkan dalam proses lain, atau bahkan limbah gas hasil pembakaran bahan bakar seperti batu bara atau gas alam. Boiler Pemulihan Panas Limbah (WHRB) digunakan untuk memulihkan energi yang terbuang sia-sia ini dan mengubahnya menjadi uap yang dapat digunakan untuk tujuan pemanasan.

Bagaimana cara kerja boiler limbah panas?

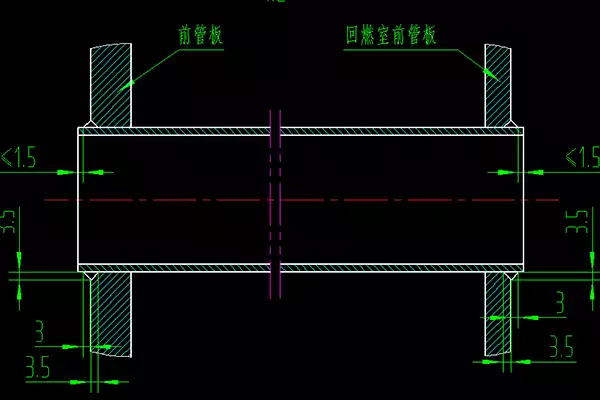

Boiler limbah panas adalah sistem tertutup, yang berarti menggunakan air sebagai fluida kerja dan pendinginnya. Air melewati tabung di dalam ketel dan menyerap panas dari gas pembakaran atau aliran pembuangan sebelum didinginkan kembali oleh udara segar yang ditarik masuk melalui kisi-kisi atau bukaan di kedua ujung setiap bundel tabung (disebut header).

Prosesnya dimulai saat Anda menyalakan mesin industri seperti tungku listrik atau mesin pembakaran. Jumlah panas berlebih mana yang tidak diperlukan oleh tujuan utamanya (Misalnya: menghasilkan listrik). Panas limbah kemudian ditransfer melalui pipa ke boiler di mana ia digunakan untuk menghangatkan air. Sampai mendidih ke dalam uap pada tekanan tinggi sebelum dilepaskan ke atmosfer melalui pipa.

Berapa kapasitas boiler panas limbah?

Kapasitas boiler panas limbah diukur Kilowatts (KW). Ini adalah jumlah listrik yang dapat dihasilkannya pada waktu tertentu. Kapasitas tergantung pada tiga faktor:

- Efisiensi sistem pemulihan panas Anda, yang mempengaruhi seberapa banyak limbah panas yang dapat Anda gunakan sebelum Anda mulai kehilangan efisiensi atau harus menambahkan lebih banyak air untuk mendinginkannya.

- Suhu sumber panas limbah Anda, serta laju alirannya (berapa banyak udara mengalir melaluinya).

- Kebutuhan Anda akan Listrik, Jika Anda hanya membutuhkan energi yang cukup untuk lampu dan peralatan satu kamar, maka kebutuhan Anda akan berbeda dari seseorang yang membutuhkan kekuatan untuk seluruh rumah atau bangunan!

Apa efisiensi boiler panas limbah?

Boiler panas limbah tidak 100% efisien. nyatanya, Biasanya ada 70% ke 80%. Itu dihitung sebagai rasio output energi terhadap input, dan biasanya dinyatakan sebagai persentase. Misalnya, Jika boiler panas limbah Anda dikonversi 80 persen bahan bakarnya menjadi panas yang bermanfaat, maka peringkat efisiensinya 0.8 (atau 80%).

Jadi jika Anda punya 1 kWh listrik yang keluar dari generator Anda yang digunakan untuk menghasilkan uap untuk proses Anda, Kemudian 0.7 - - 0.8 kWh akan hilang sebagai limbah panas melalui berbagai proses dalam sistem.

Kehilangan ini terjadi karena gesekan pada pipa dan katup serta kehilangan panas pada koil dan komponen lain yang membentuk sistem itu sendiri. (seperti pompa).

Apa saja komponen boiler limbah panas?

Komponen utama boiler limbah panas adalah:

Penukar panas primer. Ini adalah bagian dari boiler yang mentransfer panas dari satu cairan ke cairan lainnya. Biasanya terbuat dari tembaga atau stainless steel, dengan desain tabung bersirip untuk memaksimalkan efisiensi.

Sistem pengolahan air. Sistem pengolahan air membantu menghilangkan kotoran dari air Anda sebelum masuk ke boiler Anda sehingga tidak menyumbat pompa atau merusak komponen lain. Ada banyak jenis sistem perawatan yang tersedia tergantung pada jenis kotoran apa yang ada di sumber pasokan Anda.

Sistem Kontrol. Boiler panas limbah membutuhkan pemantauan konstan. Mereka membutuhkan sensor dan perangkat lunak sehingga Anda dapat mengontrol tingkat suhu selama operasi. Serta mendeteksi jika ada masalah yang terjadi di dalam sistem itu sendiri (seperti kebocoran).

Pompa umpan boiler. Pompa umpan boiler bertanggung jawab untuk memompa air dari sumur yang panas, ke dalam sistem pemanas Anda. Ini komponen yang penting. Karena itu mentransfer energi panas ke rumah atau bangunan Anda, yang memungkinkan Anda menggunakan lebih sedikit energi pada biaya pemanasan!

Tangki umpan boiler. Komponen ini menahan air pada suhu tinggi sehingga dapat digunakan oleh sistem pemanas Anda saat dibutuhkan.

Apa kelebihan dan kekurangan boiler panas limbah?

Keuntungan dari boiler panas limbah

Menghemat energi

Hemat uang untuk tagihan pemanas Anda dengan menggunakan energi yang terbuang dari proses lain di pabrik atau gedung kantor Anda.

Perlindungan Lingkungan

Kurangi emisi karena mereka tidak memerlukan bahan bakar fosil yang terbakar atau menghasilkan listrik untuk produksi panas.

Mengaktifkan biaya rendah

Ini lebih murah untuk dioperasikan daripada boiler tradisional. Karena tidak perlu biaya pengiriman bahan bakar atau perawatan. Seperti filter dan pompa yang terkait dengan boiler tradisional yang menggunakan bahan bakar fosil seperti Gas Alam atau gas propana (LPG).

Kekurangan boiler panas limbah

Biaya pemasangan mahal

Ini karena sifat kompleks boiler panas limbah dan keahlian yang diperlukan untuk pemasangan. Biaya pemasangan juga dapat bervariasi tergantung di mana Anda berada serta apakah Anda memilih listrik atau Sistem boiler berbahan bakar gas.

Lebih banyak perawatan

Mereka membutuhkan banyak perawatan karena mereka bekerja pada suhu tinggi dan menghasilkan banyak panas. Ini dapat menyebabkan korosi jika tidak dipertahankan dengan benar. Jika boiler Anda tidak dipertahankan dengan benar, itu bisa menghasilkan kinerja yang buruk. Bahkan kegagalan menyebabkan downtime untuk tanaman/bisnis Anda. Ini bisa sangat mahal terutama jika tidak ada sumber alternatif di dekatnya yang akan memungkinkan operasi untuk melanjutkan tanpa gangguan.

Bagaimana cara memilih boiler panas limbah?

Memilih boiler panas limbah adalah keputusan penting. Berikut beberapa hal yang perlu dipertimbangkan:

- Ukuran boiler. Yang besar, Boiler berkapasitas tinggi akan lebih efisien dan hemat biaya daripada yang kecil. Tetapi mungkin tidak sesuai dengan persyaratan ruang atau kendala anggaran Anda.

- Sumber panas yang digunakan untuk menghasilkan uap (MISALNYA., Listrik vs Gas Alam). Jika Anda mencari opsi ramah lingkungan yang tidak memerlukan biaya bahan bakar tambahan. Pertimbangkan panel termal matahari sebagai sumber energi alternatif untuk memanaskan air sebelum menggunakannya di sistem pemulihan panas limbah Anda!

- Biaya Instalasi dan Persyaratan Pemeliharaan (Pikirkan apakah Anda akan membutuhkan bantuan profesional dengan instalasi). Jika memasang diri sendiri bukanlah sesuatu yang terdengar menyenangkan sekarang tetapi lebih suka menghemat uang untuk orang lain yang melakukan bagian ini untuk Anda!

Berapa biaya boiler bimbah bimbah?

Itu biaya boiler panas limbah Tergantung pada sejumlah faktor termasuk ukurannya, efisiensi, dan jenis HRSG yang Anda pilih. Unit yang lebih kecil dapat dibeli hanya dengan $5,000, sedangkan yang lebih besar bisa menelan biaya $100,000.

Sistem pemulihan panas limbah adalah investasi yang layak dilakukan karena memungkinkan pengguna untuk mengurangi tagihan utilitas mereka hingga 90%. Selain itu, sistem ini ramah lingkungan karena kemampuannya tidak hanya untuk memulihkan panas. Tetapi juga untuk mendaur ulang bahan yang tidak dapat digunakan menjadi sumber energi yang dapat digunakan seperti air panas atau uap.

Kesimpulan

Kami harap artikel ini membantu Anda memahami dasar-dasar boiler limbah panas dan keuntungannya. Boiler limbah panas dapat membantu perusahaan menghemat uang untuk biaya energi sekaligus mengurangi jejak karbon mereka. Jika Anda memiliki pertanyaan tentang boiler panas limbah atau ingin informasi lebih lanjut tentang cara kerjanya, Silakan hubungi kami: +86 18623915479!

Dapatkan Harga Terbaik Anda

Bandingkan dengan cepat 3 Kutipan gratis

- Kutipan cepat insinyur

- Kecepatan pengiriman keseluruhan cepat

- Pilihan finansial

- Biaya instalasi yang rendah dan penghematan biaya

25 years+ of boiler R&D

Lebih dari 20 Teknologi Inovatif