Introduction

In the boiler industry, there are two main types of boilers: water tubes and fire tubes. Both boilers use similar heating techniques but differ in how they operate. If you’re considering purchasing a new boiler or replacing your existing one, understanding these differences can help you make an informed decision that suits your needs. In this guide, we’ll start by explaining how each type of boiler works. Then we’ll compare their sizes, weights, capacities, and efficiency ratings before wrapping things up with a comparison of their advantages and disadvantages.

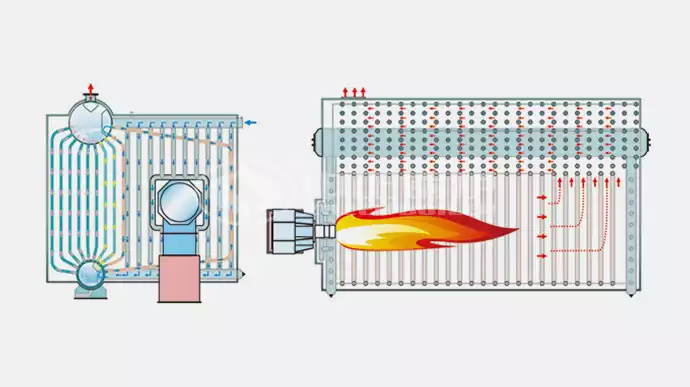

What is a Water Tube Boiler?

ए जल ट्यूब बॉयलर एक बॉयलर को संदर्भित करता है जहां उच्च तापमान वाली ग्रिप गैस बहती है और पाइप के बाहर गर्मी छोड़ती है, जबकि पानी पाइप के अंदर गर्मी को अवशोषित करता है. जो पानी बॉयलर के अंदर ट्यूबों के माध्यम से प्रसारित होता है. प्रक्रिया को चलाने वाली गर्मी अप्रत्यक्ष रूप से भट्टी से तरल में स्थानांतरित हो जाती है, जो फिर वाष्पित हो जाता है और भाप में परिवर्तित होने पर अपना दबाव बढ़ा देता है.

वॉटर ट्यूब बॉयलर का उपयोग बड़े बिजली संयंत्रों में किया जाता है, but they’re also found in smaller applications including residential heating systems and individual room furnaces.

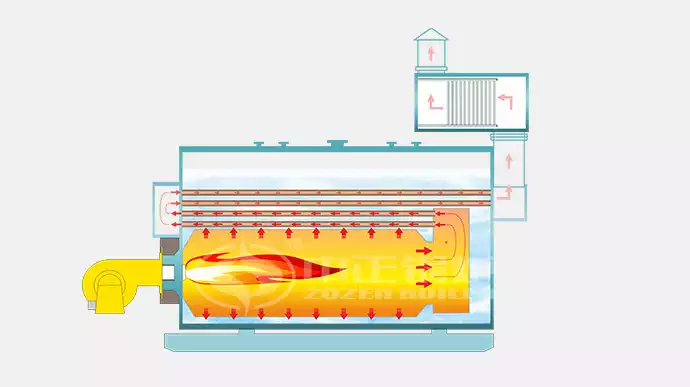

What is a Fire Tube Boiler?

Fire tube boilers are also known as shell boilers. There is a large diameter drum, a fire tube, and a large number of thin tubes inside. The smoke generated by the combustion of fuel heats the water, भाप, or steam-water mixture outside the smoke pipe, producing hot water. Fire tube boilers can be used for low-pressure steam or superheated steam, उनकी जल परिसंचरण प्रणाली के डिज़ाइन पर निर्भर करता है.

मुख्य अंतर

वॉटर ट्यूब बॉयलर की भट्टी सिलेंडर के बाहर लगाई जाती है, और भट्टी का आयतन बड़ा या छोटा हो सकता है, जो दहन और बढ़े हुए वाष्पीकरण की आवश्यकताओं को पूरा कर सकता है.

वॉटर ट्यूब बॉयलर के ड्रम को आम तौर पर सीधे गर्म नहीं किया जाता है, और जिन पाइपों में जल वाष्प होता है उन्हें भट्ठी और ग्रिप में हीटिंग सतहों के रूप में रखा जाता है, गर्मी हस्तांतरण प्रदर्शन और सुरक्षा प्रदर्शन में उल्लेखनीय सुधार हुआ.

Among the two, water tube boilers have smaller drum diameters, higher working pressure, smaller water capacity, better adaptability to load changes, and higher thermal efficiency compared to fire tube boilers.

The structure of a fire tube boiler is simple, with a fixed water level, low cost, and easy operation, while the structure of a water tube boiler is complex, requiring an additional dome steam chamber, which is expensive.

Working Principle Comparison

In a water tube boiler, water circulates in a closed circuit. Heat travels from the combustion chamber through the furnace’s tubes, then the water passes through the condenser, where it is cooled back to liquid form before returning to the starting point.

Water Tube Boilers are also known as “single pass” systems because there is only one trip for them through their various components:

- Combustion Chamber (heated by coal or oil) -> Tubes -> Heat Transfer Area Recirculation Pump -> Circulation Pump -> Water Tank

फायर ट्यूब बॉयलर में एक ओपन सर्किट डिज़ाइन होता है जहां गर्म गैसें प्रत्येक ट्यूब के एक छोर से प्रवेश करती हैं और प्रत्येक ट्यूब के भीतर पंखे और ड्राफ्ट हुड द्वारा बनाए गए दबाव अंतर के कारण दूसरे छोर से बाहर निकलती हैं।.

आकार तुलना

फायर ट्यूब बॉयलर पानी ट्यूब बॉयलर से छोटे होते हैं. एक फायर ट्यूब बॉयलर इतना छोटा हो सकता है 32 इंच दायरे में, जबकि एक वॉटर ट्यूब बॉयलर को इतना बड़ा होने की आवश्यकता हो सकती है 48 इंच समान आउटपुट प्राप्त करने के लिए व्यास में. यह फायर ट्यूबों को अधिक कॉम्पैक्ट बनाता है और तंग स्थानों में स्थापित करना आसान बनाता है.

वजन तुलना

Water tube boilers are typically heavier than fire tube boilers due to their large size, although this depends on the size of the water tube boiler. The weight of a water tube boiler can range from 5 tons to 15 tons, while fire tube boilers tend to be lighter at around 1 ton.

Capacity Comparison

When it comes to capacity, water tube boilers have a higher power rating than fire tube boilers. This is because water tubes are larger and more efficient than fire tubes. The average capacity for a water tube boiler is 1 मेगावाट या अधिक. Most fire tube boilers have capacities below 1 मेगावाट.

Efficiency Comparison

When it comes to efficiency, water tube boilers have the upper hand. Water tube boilers typically have an efficiency of 90% or above, while fire tube boilers tend to be closer to 80% efficient. The reason for this difference lies in the heating surface area and placement of tubes within each design:

- Water tubes are placed inside a boiler shell that contains steam and water, which means they get hotter than fire tubes do when exposed directly to heat from combustion gases or coal/wood fires.

- Fire tubes are surrounded by cold air rather than warm steam or hot water, so they don’t transfer as much heat into their surroundings as do their water-filled counterparts (and thus waste more energy).

Advantages Comparison

Advantages of water tube boilers

- Have a better heat transfer rate than fire tube boilers. This means that they can transfer more energy from the fuel to the water, which results in higher efficiency and lower operating costs.

- Have a longer lifespan than fire tube boilers because of their design (they have fewer moving parts).

- Are more efficient at turning fuel into heat and steam than fire tube boilers because they have better thermal conductivity between tubes and boiler walls, allowing for greater surface contact with the water inside them.

Advantages of fire tube boilers

- Better strength. Fire tube boilers have better strength than water tube boilers because the pressure vessel is made of steel and can withstand high temperatures. The pressure vessel of a water tube boiler is made of copper, which cannot withstand as much heat as steel.

- Cheaper to buy. A fire tube boiler costs less money to buy than a water tube boiler because it has fewer parts and materials used in its construction, such as iron pipes instead of copper ones, so there’s less labor involved in making them too!

हानि तुलना

- वॉटर ट्यूब बॉयलर फायर ट्यूब बॉयलर की तुलना में अधिक महंगे हैं.

- अग्नि नलियाँ जल नलिकाओं की तुलना में कम कुशल होती हैं, जिसका अर्थ है कि वे समान मात्रा में ऊष्मा या भाप उत्पन्न करने के लिए अधिक ईंधन का उपयोग करते हैं. यदि आपके पास सीमित संसाधन हैं और उन्हें यथासंभव संरक्षित करने की आवश्यकता है तो यह एक मुद्दा हो सकता है.

- बॉयलर की सुरक्षा उसके डिज़ाइन पर निर्भर करती है. लेकिन सामान्य तौर पर कहें तो, वॉटर ट्यूब बॉयलर अधिक सुरक्षित हैं. क्योंकि उनके निर्माण में उपयोग किए जाने वाले फायर ट्यूब डिज़ाइन की तुलना में विस्फोट होने की संभावना कम होती है उच्च दबाव वाली भाप or hot gasses in closed systems (like those found in power plants).

Heat exchanger Comparison

In a water tube boiler, the heat exchangers are more complex. The tubes that transfer heat can be bent into different shapes and the fluid flow is often more turbulent than in fire tube boilers. This makes it possible for a single water tube boiler to have multiple steam drums and superheaters instead of just one or two like you’d find in a fire tube design.

In contrast, fire tube boilers have less complex heat exchangers due to their simpler design which calls for straight tubes that carry both fuel gas and combustion air through them (instead of separate pipes). This makes them easier to manufacture but also results in less efficient operation when compared with their cousins–especially when running at higher temperatures or pressures where turbulence becomes important!

Security Comparison

Water tube boilers are more secure than fire tube boilers. Water tube boilers have a tighter seal between the tubes and the shell of the boiler, which means that there’s less chance for steam and water to leak out. Fire tube boilers can also be more dangerous because if one of your flues gets blocked, it could cause pressure inside your boiler to rise dangerously high. Which could lead to an explosion or other damage.

निष्कर्ष

निष्कर्ष के तौर पर, water tubes and fire tube boilers are both great options for heating your home. They both have their pros and cons, लेकिन कुल मिलाकर हमारा मानना है कि वॉटर ट्यूब बॉयलर बेहतर विकल्प हैं. फैंगकुई मुख्य रूप से विभिन्न प्रकार के फायर ट्यूब बॉयलरों का उत्पादन करता है: एकीकृत भाप बॉयलर, विभाजित भाप बॉयलर, संघनक भाप बॉयलर, क्षैतिज आंतरिक दहन कक्ष दहन बॉयलर, ऊर्ध्वाधर अग्नि ट्यूब कक्ष दहन बॉयलर, आदि. वॉटर ट्यूब बॉयलर कई प्रकार के होते हैं, जैसे डबल ड्रम वर्टिकल वॉटर ट्यूब बॉयलर, आदि. यदि आप विस्तृत मापदंडों और कीमतों के बारे में जानना चाहते हैं , कृपया हमसे सम्पर्क करें यहां +0086 186-2391-5479.

अपना सर्वश्रेष्ठ मूल्य प्राप्त करें

जल्दी से तुलना करें 3 नि: शुल्क उद्धरण

- इंजीनियर त्वरित उद्धरण

- समग्र वितरण की गति तेज है

- वित्तीय पसंद

- कम स्थापना लागत और लागत बचत

25 years+ of boiler R&D

इससे अधिक 20 नवीन प्रौद्योगिकी