مقدمة

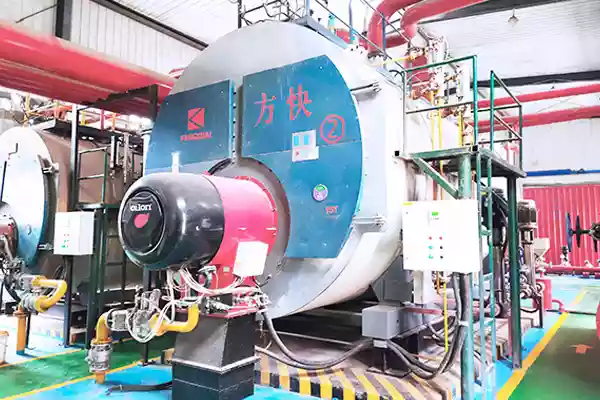

تعتبر غلايات تسخين النفايات طريقة رائعة للشركات لتحسين كفاءة الطاقة وتقليل تكلفة التدفئة والتبريد. يمكن استخدامها لاستعادة الحرارة المهدورة من العمليات الصناعية وتحويلها إلى بخار يمكن استخدامه في أنظمة التدفئة. يمكن استخدام غلايات حرارة النفايات في العديد من الصناعات المختلفة بما في ذلك المواد الكيميائية, الكيماويات البترولية, النفط والغاز, طعام, و صناعات المشروبات. في هذه المقالة, سوف تتعلم كل شيء عنها. حتى تتمكن من الاختيار الأفضل.

لماذا تستخدم غلايات الحرارة المهدرة?

تقليل استهلاك الطاقة. تقلل غلايات تسخين النفايات من كمية الطاقة التي تستخدمها لتدفئة المبنى والمياه من خلال التقاط الحرارة المتبقية من العمليات الصناعية ونقلها إلى منشأتك.

تقليل غازات الاحتباس الحراري. يمكن أن تساعدك غلايات تسخين النفايات في الحصول على شهادة LEED, وكذلك تلبية متطلبات وكالة حماية البيئة لتقليل الانبعاثات في الغلاف الجوي عن طريق التقاط ثاني أكسيد الكربون (CO2) وغيرها من الملوثات الضارة الناتجة عن حرق الوقود الأحفوري مثل الفحم أو الغاز الطبيعي لإنتاج الكهرباء.

Increase efficiency by using less fuel overall. When used in conjunction with an existing boiler system, a waste heat recovery system will increase efficiency and reduce operating costs because it reduces demand for fuel purchases while also improving overall performance at lower temperatures than traditional furnaces alone could provide on their own.

What is a waste heat boiler?

A waste heat boiler uses the exhaust heat from a process to generate steam, which is used in a steam turbine to generate electricity. The advantage of this type of system over other types of power plants is that it does not require additional fuel consumption or CO2 emissions from burning fossil fuels.

بالإضافة إلى ذلك, since waste heat boilers are often used as part of existing industrial processes (such as steel production), they can be installed without significant capital costs or changes in the manufacturing process itself.

Is a waste heat boiler a heat exchanger?

A waste heat boiler is a heat exchanger. A heat exchanger transfers heat from one medium to another. In this case, the low-temperature source is typically water that has been heated by industrial processes such as electricity generation or chemical manufacturing. The high-temperature source could be steam produced in another process, or even waste gas from the combustion of fuel like coal or natural gas. Waste Heat Recovery Boilers (WHRBs) are used to recover this otherwise wasted energy and turn it into usable steam for heating purposes.

كيف يعمل غلاية الحرارة الضائعة?

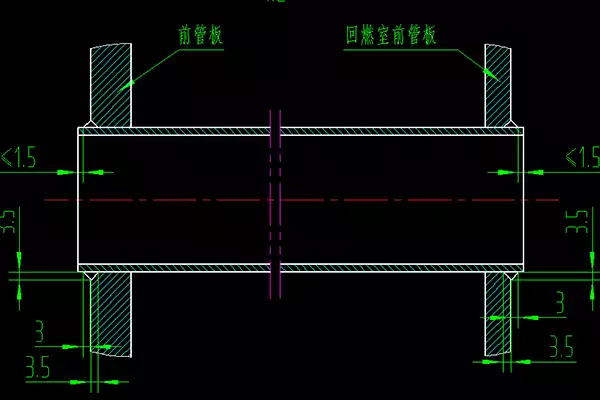

غلاية حرارة النفايات هي نظام مغلق, مما يعني أنه يستخدم الماء كسائل العمل والمبرد. يمر الماء عبر الأنابيب داخل الغلاية ويمتص الحرارة من غازات الاحتراق أو تيارات العادم قبل أن يتم تبريده مرة أخرى عن طريق الهواء النقي الذي يتم سحبه من خلال الشبكات أو الفتحات في أي من طرفي كل حزمة أنابيب (تسمى رؤوس).

تبدأ العملية عند بدء تشغيل آلة صناعية مثل فرن كهربائي أو محرك الاحتراق. Which amounts of excess heat that isn’t required by its main purpose (فمثلا: generating electricity). The waste heat is then transferred via pipes to the boiler where it is used to warm up water. Until it boils into steam at high pressure before being released into the atmosphere through a pipe.

What is the capacity of waste heat boilers?

The capacity of a waste heat boiler is measured in kilowatts (kW). This is the amount of electricity it can produce at any given time. The capacity depends on three factors:

- The efficiency of your heat recovery system, which affects how much waste heat you can use before you start losing efficiency or having to add more water to cool it down.

- The temperature of your source of waste heat, as well as its flow rate (how much air is flowing through it).

- Your needs for electricity, if you only need enough energy for one room’s worth of lights and appliances, then your requirements will be different than someone who needs power for an entire house or building!

What is the efficiency of a waste heat boiler?

A waste heat boiler is not 100% efficient. في الواقع, it’s usually around 70% إلى 80%. It’s calculated as the ratio of energy output to input, and it’s usually expressed as a percentage. فمثلا, if your waste heat boiler converts 80 percent of its fuel into useful heat, then its efficiency rating would be 0.8 (أو 80%).

So if you have 1 kWh of electricity coming out from your generator which is being used to produce steam for your process, then 0.7 - 0.8 كيلوواط ساعة will be lost as waste heat through various processes within the system.

This loss occurs due to friction in pipes and valves as well as heat losses in coils and other components that make up the system itself (like pumps).

What are the components of waste heat boilers?

The main components of a waste heat boiler are:

Primary heat exchanger. This is the part of the boiler that transfers heat from one fluid to another. It’s usually made of copper or stainless steel, with a finned tube design to maximize efficiency.

Water treatment system. A water treatment system helps remove impurities from your water before it goes into your boiler so that it doesn’t clog up pumps or damage other components. There are many different types of treatment systems available depending on what kind of impurities are present in your supply source.

Control system. Waste heat boilers require constant monitoring. They need sensors and software so that you can control temperature levels throughout the operation. As well as detect if there are any problems occurring within the system itself (like leaks).

Boiler feed pump. The boiler feed pump is responsible for pumping water from the hot well, into your heating system. It’s an important component. Because it transfers heat energy to your home or building, which allows you to use less energy on heating costs!

Boiler feed tank. This component holds water at high temperatures so that it can be used by your heating system when needed.

What are the advantages and disadvantages of waste heat boilers?

Advantages of waste heat boilers

Save Energy

Save money on your heating bill by using the wasted energy from other processes in your plant or office building.

Environmental Protection

Reduce emissions because they don’t require burning fossil fuels or producing electricity for heat production.

Running Low Cost

These are less expensive to operate than traditional boilers. Because there is no need for fuel delivery or maintenance costs. Such as filters and pumps associated with traditional boilers that use fossil fuels like غاز طبيعي أو propane gas (غاز البترول المسال).

Disadvantages of waste heat boilers

Installation Cost Expensive

This is because of the complex nature of waste heat boilers and the expertise required for installation. The installation costs may also vary depending on where you’re located as well as whether you choose an electric or نظام غلاية تعمل بالغاز.

مزيد من الصيانة

إنها تتطلب الكثير من الصيانة لأنها تعمل في درجات حرارة عالية وتولد الكثير من الحرارة. هذا يمكن أن يؤدي إلى التآكل إذا لم تتم صيانته بشكل صحيح. إذا لم تتم صيانة غلايتك بشكل صحيح ، فقد يؤدي ذلك إلى ضعف الأداء. حتى الفشل يتسبب في توقف مصنعك / عملك. قد يكون هذا مكلفًا للغاية خاصةً إذا لم يكن هناك مصدر بديل قريب من شأنه أن يسمح باستمرار العمليات دون انقطاع.

كيف أختار غلاية الحرارة الضائعة?

Choosing a waste heat boiler is an important decision. Here are some things to consider:

- The size of the boiler. A large, high-capacity boiler will be more efficient and cost-effective than a small one. But it may not fit your space requirements or budget constraints.

- The heat source used to generate steam (على سبيل المثال, electricity vs natural gas). If you’re looking for an environmentally friendly option that requires no additional fuel costs. Consider solar thermal panels as an alternative energy source for heating water before using them in your waste heat recovery system!

- Installation costs and maintenance requirements (think about whether you’ll need professional help with installation). If installing yourself isn’t something that sounds fun right now but would rather save money on someone else doing this part for you!

How much does a waste heat boiler cost?

ال cost of an waste heat boiler depends on a number of factors including the size, نجاعة, and type of HRSG you choose. Smaller units can be purchased for as little as $5,000, while larger ones can cost over $100,000.

A waste heat recovery system is an investment worth making because it allows users to reduce their utility bills by up to 90%. فضلاً عن ذلك, these systems are environmentally friendly due to their ability not only to recover heat. But also to recycle otherwise unusable materials into usable energy sources such as hot water or steam.

استنتاج

نأمل أن تكون هذه المقالة قد ساعدتك في فهم أساسيات غلايات الحرارة المهدرة ومزاياها. يمكن أن تساعد غلايات تسخين النفايات الشركات في توفير المال على تكاليف الطاقة مع تقليل انبعاثات الكربون أيضًا. إذا كان لديك أي أسئلة حول غلايات الحرارة المهدرة أو تريد المزيد من المعلومات حول كيفية عملها, الرجاء التواصل معنا: +86 18623915479!

احصل على أفضل سعر لك

قارن بسرعة 3 اقتباسات مجانية

- مهندس اقتباس سريع

- سرعة التسليم الإجمالية سريعة

- الاختيار المالي

- تكاليف التثبيت المنخفضة وتوفير التكاليف

25 years+ of boiler R&D

أكثر من 20 التقنيات المبتكرة